Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear drive shaft assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

| Rear wheel alignment adjustment |

- Perform "Reset Memory"

- Perform acceleration sensor zero point calibration and system information memorization

|

- VSC disabled or malfunctioning

- DTCs are output

- Slip indicator light illuminated

- ABS warning light illuminated

|

.gif)

.gif) |

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

.gif) for Initialization for Initialization

.gif) for Calibration for Calibration |

- Television camera controller initialization

- Adjust steering angle

- Rear television camera assembly optical axis (Back camera position setting)

| Panoramic view monitor system |

.gif) for Initialization for Initialization

.gif) for Calibration for Calibration |

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

Click here

.gif)

2. REMOVE REAR AXLE CARRIER

Click here .gif)

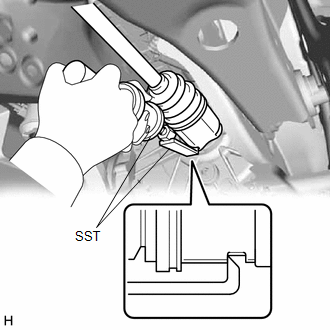

3. REMOVE REAR DRIVE SHAFT ASSEMBLY LH

| (a) Using SST, remove the rear drive shaft assembly LH from the rear differential carrier assembly.

SST: 09520-01011 SST: 09520-20010 09521-02010 09521-02040

09521-02060

NOTICE:

- Do not damage the rear drive shaft oil seal.

- Do not damage the inboard joint boot.

- Do not drop the rear drive shaft assembly LH.

- When removing the rear drive shaft assembly LH, keep it level.

| |

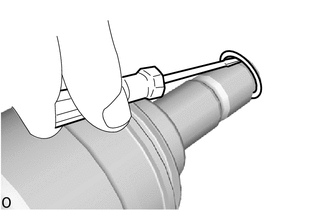

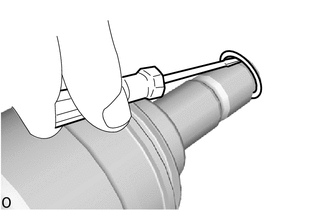

4. REMOVE REAR DRIVE SHAFT INBOARD JOINT SHAFT SNAP RING LH

(a) Using a screwdriver, remove the rear drive shaft inboard joint shaft snap ring LH.

READ NEXT:

DISASSEMBLY CAUTION / NOTICE / HINT

NOTICE:

When using a vise, place aluminum plates between the part and vise.

When using a vise, do not overtighten it.

HINT:

Use the same procedur

INSPECTION CAUTION / NOTICE / HINT

NOTICE:

When using a vise, place aluminum plates between the part and vise.

When using a vise, do not overtighten it.

PROCEDURE 1. INSPECT REAR DRIVE S

REASSEMBLY CAUTION / NOTICE / HINT

NOTICE:

When using a vise, place aluminum plates between the part and vise.

When using a vise, do not overtighten it.

HINT:

Use the same procedure

SEE MORE:

GENERAL INFORMATION GENERAL DESCRIPTION (a) This manual is written in accordance with SAE J2008.

(b) Repair operations can be separated mainly into the following 3 processes:

(1) Diagnosis (2) Removing/Installing, Replacing, Disassembling/Reassembling, Checking and Adjusting

(3) Final Inspecti

DESCRIPTION LOCATION

*1 Vacuum Switching Valve (for Active Control Engine Mount System)

*2 Front Engine Mounting Insulator

*3 Rear Engine Mounting Insulator

- -

The active control engine mount system decreases engine vibration at a low engine speed using th

.gif)

.gif)