Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during transmission control cable assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: When the ECM is replaced with a new one, reset memory is unnecessary. | |||

| Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision system | |||

|

Memorize steering angle neutral point |

Parking assist monitor system |

| |

|

Panoramic view monitor system |

| ||

|

Replacement of ECM | Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

| |

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

|

| for Initialization for Registration |

|

Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

| ||

| Replacement of ECM |

Code registration |

|

|

PROCEDURE

1. REMOVE BATTERY

Click here .gif)

2. REMOVE ECM

Click here .gif)

3. REMOVE BATTERY CLAMP SUB-ASSEMBLY

Click here

.gif)

.gif)

4. REMOVE FRONT EXHAUST PIPE ASSEMBLY (TWC: Rear Catalyst)

Click here

.gif)

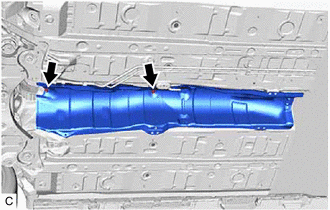

5. REMOVE FRONT LOWER NO. 1 FLOOR HEAT INSULATOR

| (a) Remove the 2 nuts and front lower No. 1 floor heat insulator from the vehicle body. |

|

6. REMOVE TRANSMISSION FLOOR SHIFT ASSEMBLY

Click here

.gif)

7. REMOVE NO. 1 CONSOLE BOX DUCT

| (a) Remove the No. 1 console box duct. |

|

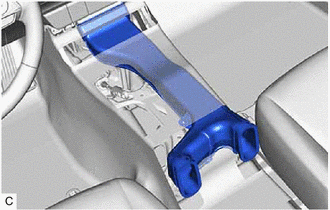

8. REMOVE TRANSMISSION CONTROL CABLE ASSEMBLY

| (a) While disengaging the clip as shown in the illustration, disconnect the transmission control cable assembly from the transmission control shaft lever together with the clip. |

|

.png)