Toyota Camry (XV70): Components

COMPONENTS

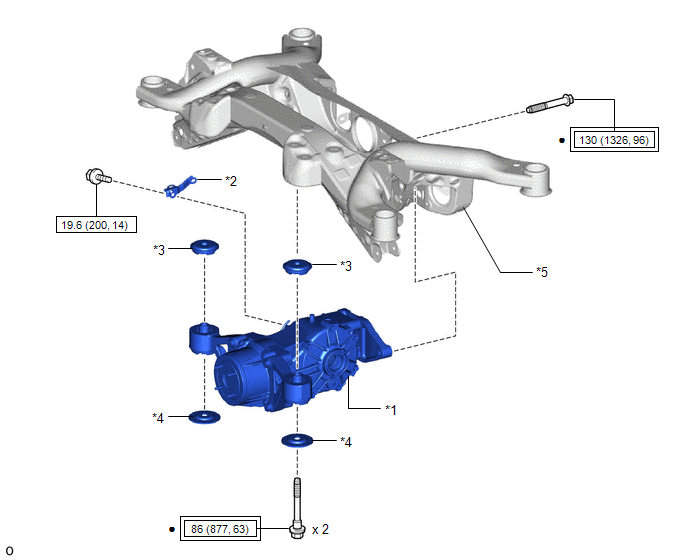

ILLUSTRATION

|

*1 | REAR DIFFERENTIAL CARRIER ASSEMBLY |

*2 | WIRE HARNESS CLAMP BRACKET |

|

*3 | REAR UPPER DIFFERENTIAL MOUNT STOPPER |

*4 | REAR LOWER DIFFERENTIAL MOUNT STOPPER |

|

*5 | REAR SUSPENSION MEMBER SUB-ASSEMBLY |

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

- | - |

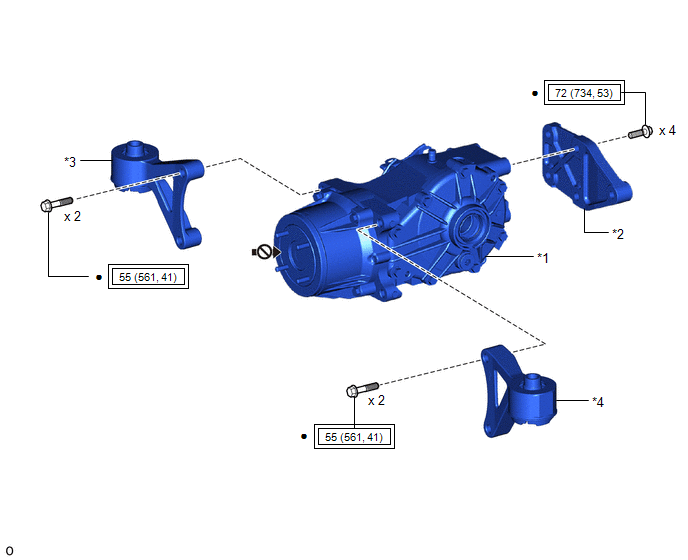

ILLUSTRATION

|

*1 | REAR DIFFERENTIAL CARRIER ASSEMBLY |

*2 | REAR DIFFERENTIAL SUPPORT |

|

*3 | REAR NO. 1 DIFFERENTIAL SUPPORT |

*4 | REAR NO. 2 DIFFERENTIAL SUPPORT |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

● | Non-reusable part |

.png) |

Do not apply lubricants to the threaded parts |

- | - |

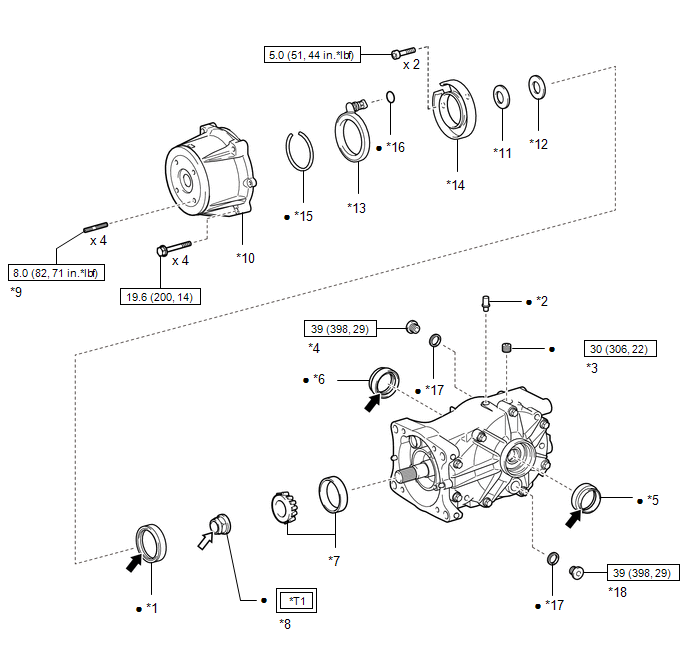

ILLUSTRATION

|

*1 | DIAPHRAGM OIL SEAL |

*2 | REAR DIFFERENTIAL CARRIER COVER BREATHER PLUG |

|

*3 | REAR DIFFERENTIAL CARRIER COVER PLUG |

*4 | REAR DIFFERENTIAL FILLER PLUG |

|

*5 | REAR DRIVE SHAFT OIL SEAL LH |

*6 | REAR DRIVE SHAFT OIL SEAL RH |

|

*7 | REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

*8 | REAR DRIVE PINION NUT |

|

*9 | STUD BOLT |

*10 | TRANSMISSION COUPLING ASSEMBLY |

|

*11 | TRANSMISSION COUPLING CONICAL SPRING WASHER |

*12 | TRANSMISSION COUPLING SHIM |

|

*13 | 4WD LINEAR SOLENOID |

*14 | YOKE |

|

*15 | SNAP RING |

*16 | O-RING |

|

*17 | GASKET |

*18 | REAR DIFFERENTIAL DRAIN PLUG |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

* | For use with SST |

● | Non-reusable part |

.png) |

MP grease |

.png) |

When reusing part: Hypoid gear oil LSD |

|

★ | Precoated part |

- | - |

|

*T1 | For use without SST: 245 N*m (2498 kgf*cm, 181 ft.*lbf) or less For use with SST: 226 N*m (2305 kgf*cm, 167 ft.*lbf) or less |

- | - |

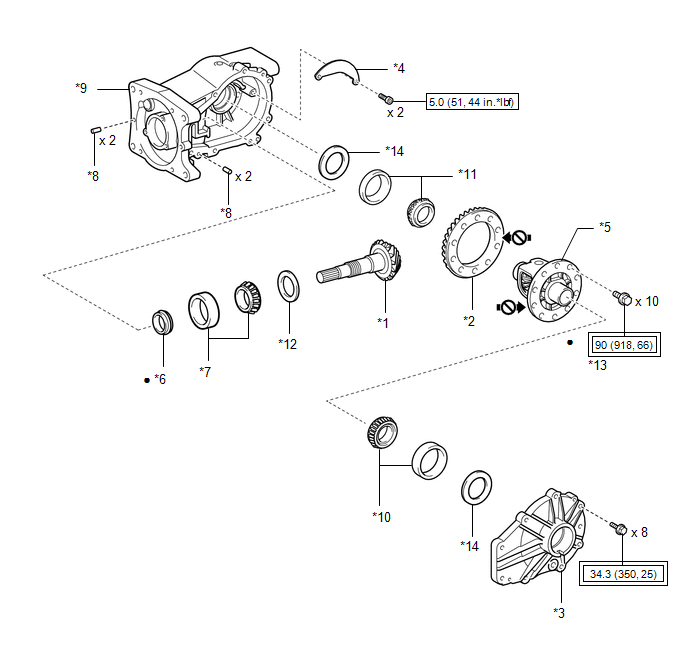

ILLUSTRATION

|

*1 | DIFFERENTIAL DRIVE PINION |

*2 | DIFFERENTIAL RING GEAR |

|

*3 | DIFFERENTIAL SIDE BEARING RETAINER |

*4 | REAR DIFFERENTIAL BREATHER PLUG OIL DEFLECTOR |

|

*5 | REAR DIFFERENTIAL CASE SUB-ASSEMBLY |

*6 | REAR DIFFERENTIAL DRIVE PINION BEARING SPACER |

|

*7 | REAR DRIVE PINION REAR BEARING |

*8 | STRAIGHT PIN |

|

*9 | REAR DIFFERENTIAL CARRIER SUB-ASSEMBLY |

*10 | REAR DIFFERENTIAL CASE BEARING LH |

|

*11 | REAR DIFFERENTIAL CASE BEARING RH |

*12 | REAR DIFFERENTIAL DRIVE PINION WASHER |

|

*13 | REAR DIFFERENTIAL CASE BOLT |

*14 | REAR DIFFERENTIAL SIDE GEAR SHAFT WASHER |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

.png) |

Do not apply lubricants to the threaded parts |