Toyota Camry (XV70): Cooling System

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

Do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

.png)

PROCEDURE

1. INSPECT FOR COOLANT LEAK

CAUTION:

Do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

(a) Remove the radiator cap sub-assembly.

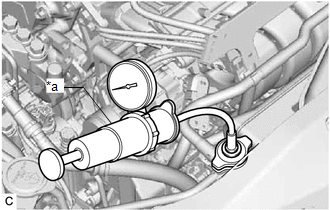

| (b) Fill the radiator assembly with engine coolant, and then install a radiator cap tester. |

|

(c) Warm up the engine.

(d) Pump the radiator cap tester to 103 kPa (1.1 kgf/cm2, 15 psi), and then check that the pressure does not drop.

- If the pressure drops, check the hoses, radiator assembly and engine water pump assembly (water inlet housing) for leaks.

- If there are no signs of external engine coolant leaks, check the heater core, cylinder block sub-assembly and cylinder head sub-assembly.

(e) Remove the radiator cap tester.

(f) Install the radiator cap sub-assembly.

2. INSPECT ENGINE COOLANT LEVEL IN RESERVOIR TANK

| (a) Check that the engine coolant level is between the L line and F line when the engine is cold. If the engine coolant level is low, check for leaks and add engine coolant to the F line. NOTICE: Do not substitute plain water for engine coolant. |

|

3. INSPECT ENGINE COOLANT QUALITY

CAUTION:

Do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

(a) Remove the radiator cap sub-assembly.

(b) Check if there are any excessive deposits of rust or scale around the radiator cap sub-assembly and water filler hole. Also, the engine coolant should be free of oil.

If excessively dirty, replace the engine coolant.

(c) Install the radiator cap sub-assembly.

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

Do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

.png)

PROCEDURE

1. INSPECT FOR COOLANT LEAK

CAUTION:

Do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

(a) Remove the radiator cap sub-assembly.

| (b) Fill the radiator assembly with engine coolant, and then install a radiator cap tester. |

|

(c) Warm up the engine.

(d) Pump the radiator cap tester to 103 kPa (1.1 kgf/cm2, 15 psi), and then check that the pressure does not drop.

- If the pressure drops, check the hoses, radiator assembly and engine water pump assembly (water inlet housing) for leaks.

- If there are no signs of external engine coolant leaks, check the heater core, cylinder block sub-assembly and cylinder head sub-assembly.

(e) Remove the radiator cap tester.

(f) Install the radiator cap sub-assembly.

2. INSPECT ENGINE COOLANT LEVEL IN RESERVOIR TANK

| (a) Check that the engine coolant level is between the L line and F line when the engine is cold. If the engine coolant level is low, check for leaks and add engine coolant to the F line. NOTICE: Do not substitute plain water for engine coolant. |

|

3. INSPECT ENGINE COOLANT QUALITY

CAUTION:

Do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

(a) Remove the radiator cap sub-assembly.

(b) Check if there are any excessive deposits of rust or scale around the radiator cap sub-assembly and water filler hole. Also, the engine coolant should be free of oil.

If excessively dirty, replace the engine coolant.

(c) Install the radiator cap sub-assembly.

.png)

.png)

.png)