Toyota Camry (XV70): Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR ENGINE OIL SEAL

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly level.

- To prevent the No. 2 oil pan sub-assembly from deforming, do not place any attachments under the No. 2 oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

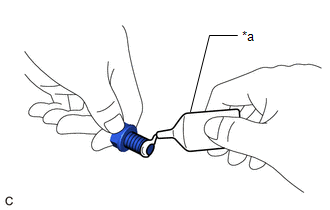

| (b) Apply MP grease to the lip of a new rear engine oil seal. NOTICE:

|

|

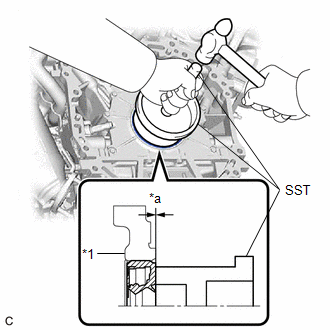

(c) Using SST and a hammer, tap in the rear engine oil seal.

SST: 09223-15030

SST: 09950-70010

09951-07150

Oil Seal Protrusion Height:

-0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

NOTICE:

Do not tap in the rear engine oil seal at an angle.

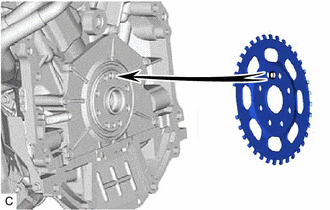

2. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR PLATE

| (a) Install the No. 1 crankshaft position sensor plate. HINT: Align the pin of the No. 1 crankshaft position sensor plate with the pin hole of the crankshaft. |

|

3. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

| (a) Using SST, hold the crankshaft pulley. SST: 09213-70011 09213-70020 SST: 09330-00021 |

|

(b) Clean the 8 bolts and 8 bolt holes.

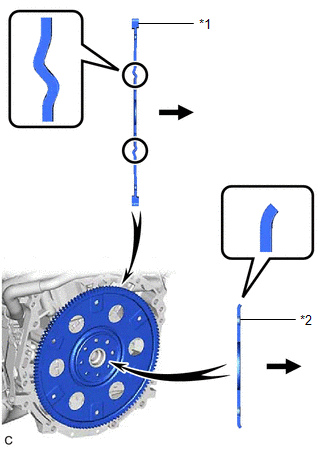

(c) Install the drive plate and ring gear sub-assembly and rear drive plate spacer to the crankshaft.

|

*1 | Drive Plate and Ring Gear Sub-assembly |

|

*2 | Rear Drive Plate Spacer |

.png) |

Transaxle Side |

| (d) Apply adhesive to 2 or 3 threads at the end of each of the 8 bolts. Adhesive: Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent |

|

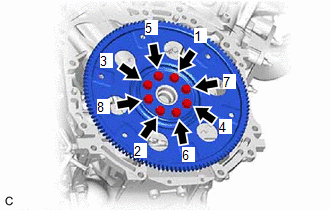

| (e) Install and uniformly tighten the 8 bolts in several steps in the sequence shown in the illustration. Torque: 83 N·m {846 kgf·cm, 61 ft·lbf} NOTICE: Do not start the engine for at least 1 hour after installing the drive plate and ring gear sub-assembly. |

|

4. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

Click here

.gif)

.gif)

.png)