Toyota Camry (XV70): Diagnosis System

DIAGNOSIS SYSTEM

DESCRIPTION

(a) When troubleshooting On-Board Diagnostic (OBD II) vehicles, an OBD II scan tool (complying with SAE J1978) must be connected to the vehicle. Various data output from the vehicle ECM can then be read.

(b) OBD II regulations require that the vehicle on-board computer illuminate the Malfunction Indicator Lamp (MIL) on the instrument panel when the computer detects a malfunction in:

- The emission control system/components

- The powertrain control components which affect vehicle emissions

- The computer

In addition, the applicable Diagnostic Trouble Codes (DTCs) prescribed by SAE J2012 are recorded in the ECM memory.

If a malfunction does not recur, the MIL remains illuminated until the engine switch is turned off, and the MIL turns off when the engine is started. However, the DTCs will remain recorded in the ECM memory.

(c) To check DTCs, connect the Techstream to the Data Link Connector 3 (DLC3) of the vehicle. The Techstream displays DTCs, freeze frame data and a variety of engine data.

The DTCs and freeze frame data can be cleared with the Techstream.

Click here

.gif)

NORMAL MODE AND CHECK MODE

(a) The diagnosis system operates in normal mode during normal vehicle use. In normal mode, 2 trip detection logic is used to ensure accurate detection of malfunctions. Check mode is also available as an option for technicians. In check mode, 1 trip detection logic is used to increase the system's ability to detect malfunctions, including intermittent problems, when simulating malfunction symptoms (Techstream only).

2 TRIP DETECTION LOGIC

(a) When a malfunction is first detected, the malfunction is temporarily stored in the ECM memory (1st trip). If the same malfunction is detected during the next driving cycle, the MIL is illuminated (2nd trip).

FREEZE FRAME DATA

(a) The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air/fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

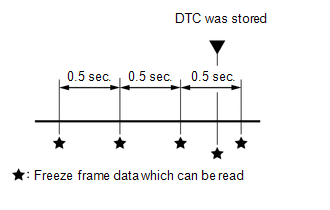

(b) The Techstream records freeze frame data in 5 different instances: 1) 3 times before a DTC is stored, 2) once when a DTC is stored, and 3) once after a DTC is stored. These sets of data can be used to simulate the vehicle condition around the time when the malfunction occurred. The data may help in diagnosing the malfunction, or in judging if the DTC was stored due to a temporary malfunction.

CHECK DATA LINK CONNECTOR 3 (DLC3)

(a) Check the DLC3.

Click here .gif)

CHECK BATTERY VOLTAGE

Standard Voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery.

CHECK MIL

(a) Check that the MIL illuminates when the engine switch is turned on (IG) (engine not started).

(b) The MIL should turn off when the engine is started. If the MIL remains illuminated, the diagnosis system has detected a malfunction in the system.

HINT:

If the MIL is not illuminated when the engine switch is turned on (IG), check the MIL circuit.

Click here .gif)