Toyota Camry (XV70): Drive Mode Select Switch Circuit

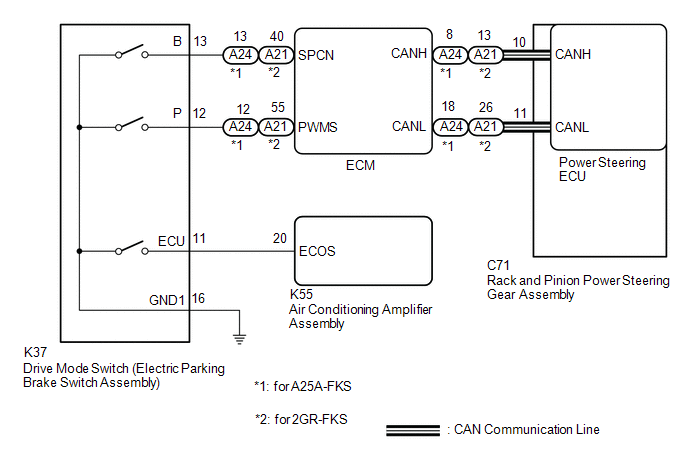

DESCRIPTION

The electronic throttle and the EPS character change by the operation of the drive mode switch (electric parking brake switch assembly).

WIRING DIAGRAM

PROCEDURE

|

1. | CHECK THE PROBLEM SYMPTOMS |

(a) Check each symptom by checking the suspected areas in the table below.

|

Result | Proceed to |

|---|---|

|

SPORT mode or NORMAL mode is abnormal. |

A |

| ECO mode is abnormal. |

B |

| B | .gif) |

GO TO AIR CONDITIONING SYSTEM |

|

|

2. | CHECK CAN COMMUNICATION SYSTEM |

(a) Check for DTCs.

Click here

.gif)

|

Result | Proceed to |

|---|---|

|

CAN communication system DTCs are not output. |

A |

| CAN communication system DTCs are output. |

B |

| B | .gif) |

GO TO CAN COMMUNICATION SYSTEM |

|

|

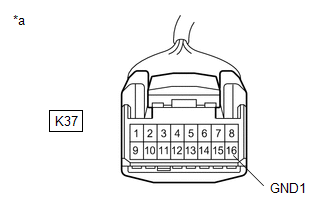

3. | CHECK HARNESS AND CONNECTOR (DRIVE MODE SWITCH (ELECTRIC PARKING BRAKE SWITCH ASSEMBLY) - BODY GROUND) |

(a) Turn the ignition switch off.

| (b) Disconnect the K37 drive mode switch (electric parking brake switch assembly) connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K37-16 (GND1) - Body ground |

Always | Below 1 Ω |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. | INSPECT DRIVE MODE SWITCH (ELECTRIC PARKING BRAKE SWITCH ASSEMBLY) |

(a) Inspect drive mode switch (electric parking brake switch assembly).

for UA80E: Click here .gif)

for UB80E: Click here

.gif)

for UB80F: Click here

.gif)

OK:

Drive mode switch (electric parking brake switch assembly) is normal.

|

Result | Proceed to |

|---|---|

|

CAN communication system DTCs are not output. (for A25A-FKS) |

A |

| CAN communication system DTCs are not output. (for 2GR-FKS) |

B |

| CAN communication system DTCs are output. |

C |

| B | .gif) |

GO TO STEP 6 |

| C | .gif) |

REPLACE ELECTRIC PARKING BRAKE SWITCH ASSEMBLY SWITCH ASSEMBLY for UA80E: Click here for UB80E: Click here

for UB80F: Click here

|

|

|

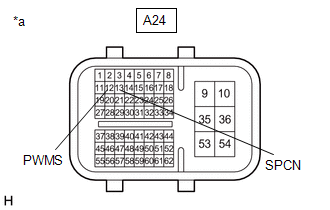

5. | CHECK HARNESS AND CONNECTOR (DRIVE MODE SWITCH (ELECTRIC PARKING BRAKE SWITCH ASSEMBLY) - ECM) |

(a) Reconnect the K37 drive mode switch (electric parking brake switch assembly) connector.

| (b) Disconnect the A24 ECM connectors. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A24-12 (PWMS) - Body ground |

SPORT mode switch being turned and held |

Below 1 Ω |

|

A24-12 (PWMS) - Body ground |

SPORT mode switch not turned |

10 kΩ or higher |

|

A24-13 (SPCN) - Body ground |

NORMAL mode switch being pushed and held |

Below 1 Ω |

|

A24-13 (SPCN) - Body ground |

NORMAL mode switch not pushed |

10 kΩ or higher |

| OK | .gif) |

REPLACE ECM |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

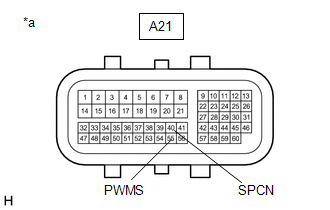

6. | CHECK HARNESS AND CONNECTOR (DRIVE MODE SWITCH (ELECTRIC PARKING BRAKE SWITCH ASSEMBLY) - ECM) |

(a) Reconnect the K37 drive mode switch (electric parking brake switch assembly) connector.

| (b) Disconnect the A21 ECM connectors. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A21-55 (PWMS) - Body ground |

SPORT mode switch being turned and held |

Below 1 Ω |

| A21-55 (PWMS) - Body ground |

SPORT mode switch not turned |

10 kΩ or higher |

|

A21-40 (SPCN) - Body ground |

NORMAL mode switch being pushed and held |

Below 1 Ω |

|

A21-40 (SPCN) - Body ground |

NORMAL mode switch not pushed |

10 kΩ or higher |

| OK | .gif) |

REPLACE ECM |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)