Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT DRIVE SHAFT ASSEMBLY

| (a) Check that there is no excessive play in the radial direction of the outboard joint. |

|

(b) Check that the inboard joint slides smoothly in the thrust direction.

(c) Check that there is no excessive play in the radial direction of the inboard joint.

(d) Check the boots for damage.

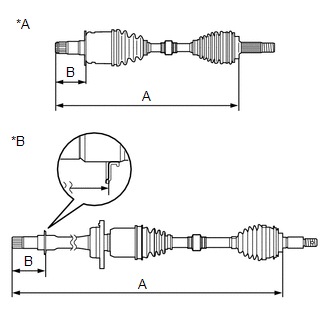

| (e) Check whether the drive shaft dimension (A) and (B) are within specification. NOTICE: Keep the drive shaft assembly level during inspection. Dimension (A):

Dimension (B):

|

| ||||||||||||||||||||||

READ NEXT:

Reassembly

Reassembly

REASSEMBLY CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. INSTALL FRONT DRIVE SHAFT BEARING (f

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. INSTALL FRONT DRIVE SHAFT HOLE SNA

SEE MORE:

Components

Components

COMPONENTS ILLUSTRATION

*1 INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU

*2 NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf): Specified torque

- - ILLUSTRATION

*1 MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU

Operation Check

Operation Check

OPERATION CHECK STORAGE CHECK

NOTICE:

When replacing the radio and display receiver assembly, always replace it with a new one. If a radio and display receiver assembly which was installed to another vehicle is used, the following may occur:

A communication malfunction DTC may be stored.

© 2023-2026 Copyright www.tocamry.com

.png)