Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT PADDLE SWITCH (TRANSMISSION SHIFT SWITCH ASSEMBLY)

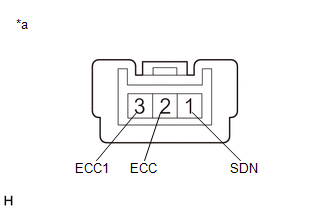

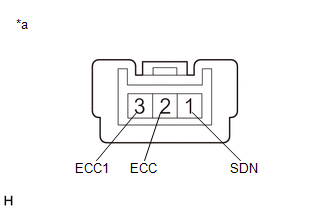

(a) Shift Paddle Switch LH (Transmission Shift Switch Assembly):

| (1) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

1 (SDN) - 2 (ECC) |

"-" (Down shift) shift paddle switch operated and held |

Below 2.5 Ω | |

"-" (Down shift) shift paddle switch not operated |

1 MΩ or higher | |

1 (SDN) - 3 (ECC1) |

"-" (Down shift) shift paddle switch operated and held |

Below 2.5 Ω | |

"-" (Down shift) shift paddle switch not operated |

1 MΩ or higher | If the result is not as specified, replace the shift paddle switch LH (transmission shift switch assembly). |

|

|

*a | Component without harness connected

(Shift Paddle Switch LH (Transmission Shift Switch Assembly)) | | |

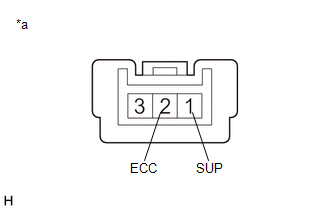

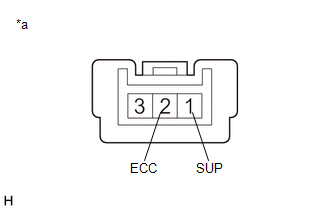

(b) Shift Paddle Switch RH (Transmission Shift Switch Assembly):

| (1) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

1 (SUP) - 2 (ECC) |

"+" (Up shift) shift paddle switch operated and held |

Below 2.5 Ω | |

"+" (Up shift) shift paddle switch not operated |

1 MΩ or higher | If the result is not as specified, replace the shift paddle switch RH (transmission shift switch assembly). |

|

|

*a | Component without harness connected

(Shift Paddle Switch RH (Transmission Shift Switch Assembly)) | | |

READ NEXT:

INSTALLATION PROCEDURE 1. INSTALL NO. 1 SWITCH WIRE

HINT: Perform this procedure only when replacement of the No. 1 switch wire is necessary.

(a) Engage the 2 guides to install the No. 1 switch wi

ComponentsCOMPONENTS ILLUSTRATION

*1 TRANSMISSION REVOLUTION SENSOR (NC)

*2 TRANSMISSION REVOLUTION SENSOR (NT)

*3 SPACER

- -

Tightening torque for

InspectionINSPECTION PROCEDURE

1. INSPECT TORQUE CONVERTER ASSEMBLY (a) Inspect the one-way clutch. Press on the splines of the stator with a finger and rotate it. Check that it rotates smoothly whe

SEE MORE:

DESCRIPTION The tire pressure warning ECU and receiver receives signals from the skid control ECU (brake actuator assembly) via CAN communication system.

DTC No. Detection Item

DTC Detection Condition Trouble Area

Note U0129

Lost Communication with Brake System Control

REMOVAL CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during mass air flow meter sub-assembly removal/installation are shown below. Necessary Procedures After Part