Toyota Camry (XV70): Speed Sensor

Components

COMPONENTS

ILLUSTRATION

|

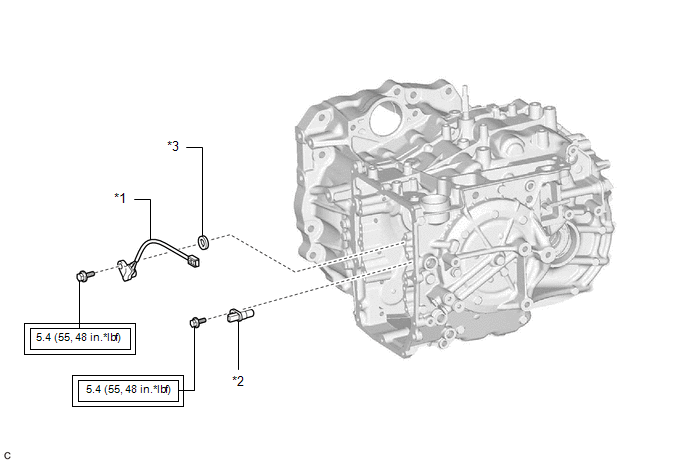

*1 | TRANSMISSION REVOLUTION SENSOR (NC) |

*2 | TRANSMISSION REVOLUTION SENSOR (NT) |

|

*3 | SPACER |

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

- | - |

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during transmission revolution sensor (NT) and transmission revolution sensor (NC) removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

|

Transmission valve body assembly |

|

|

|

PROCEDURE

1. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

Click here

.gif)

2. REMOVE TRANSMISSION REVOLUTION SENSOR (NT)

| (a) Remove the bolt and transmission revolution sensor (NT) from the automatic transaxle case sub-assembly. |

|

3. REMOVE TRANSMISSION REVOLUTION SENSOR (NC)

| (a) Remove the bolt, spacer and transmission revolution sensor (NC) from the counter drive gear sub-assembly. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION REVOLUTION SENSOR (NC)

(a) Install the transmission revolution sensor (NC) and spacer to the counter drive gear sub-assembly with the bolt.

Torque:

5.4 N

.png)

.png)