Toyota Camry (XV70): LIN Communication Bus Malfunction (B2325)

DESCRIPTION

If the main body ECU (multiplex network body ECU) detects a communication error with an ECU connected to the door bus lines for 8 seconds or more, DTC B2325 will be stored.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

|---|---|---|---|

|

B2325 | LIN Communication Bus Malfunction |

The main body ECU (multiplex network body ECU) detects a communication error with an ECU connected to the door bus lines for 8 seconds or more. |

|

- *1: w/ Sliding Roof System

- *2: w/ Panoramic Moon Roof System

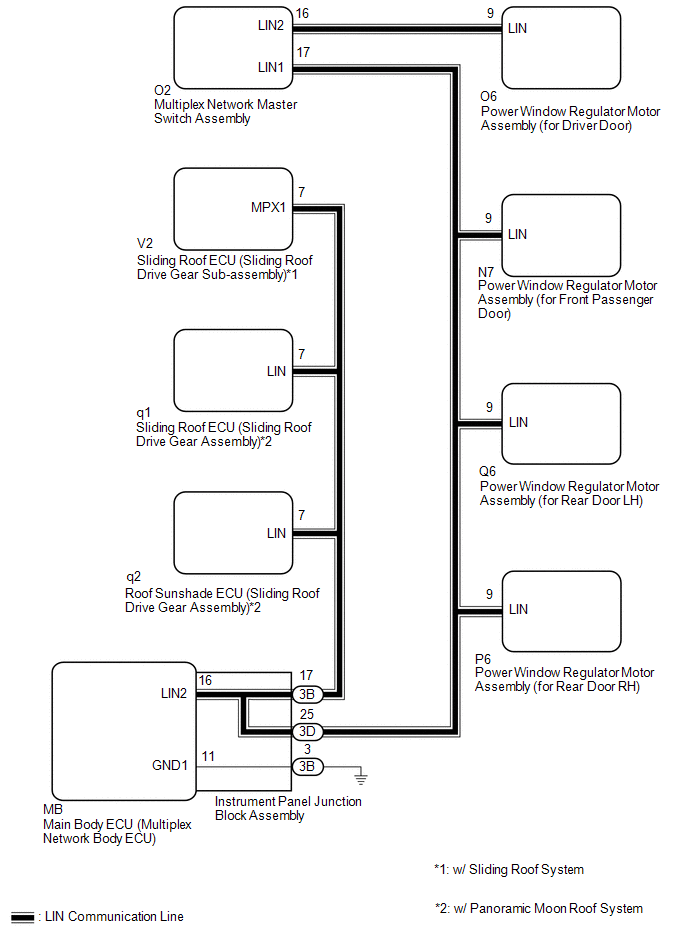

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When a power window regulator motor assembly is replaced or removed and reinstalled, it is necessary to perform initialization.

Click here

.gif)

- When the sliding roof ECU (sliding roof drive gear sub-assembly) is replaced or removed and reinstalled, it is necessary to perform initialization.*1

Click here

.gif)

- When the sliding roof ECU (sliding roof drive gear assembly) or roof sunshade ECU (sliding roof drive gear assembly) is replaced or removed and reinstalled, it is necessary to perform initialization.*2

Click here

.gif)

- Before replacing the main body ECU (multiplex network body ECU), refer to Registration.*3

Click here

.gif)

.gif)

.gif)

- *1: w/ Sliding Roof System

- *2: w/ Panoramic Moon Roof System

- *3: w/ Smart Key System

PROCEDURE

|

1. | CHECK POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Driver Door) |

(a) Disconnect the O6 power window regulator motor assembly (for driver door) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B2325 is output | A |

|

DTC B2325 is not output |

B |

| B |

.gif) | REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Driver Door)

|

|

| 2. |

CHECK MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY |

(a) Disconnect the O2 multiplex network master switch assembly connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B2325 is output | A |

|

DTC B2325 is not output |

B |

| B |

.gif) | GO TO STEP 13 |

|

| 3. |

CHECK POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Front Passenger Door) |

(a) Disconnect the N7 power window regulator motor assembly (for front passenger door) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B2325 is output | A |

|

DTC B2325 is not output |

B |

| B |

.gif) | REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Front Passenger Door)

|

|

| 4. |

CHECK POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Rear Door RH) |

(a) Disconnect the P6 power window regulator motor assembly (for rear door RH) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B2325 is output | A |

|

DTC B2325 is not output |

B |

| B |

.gif) | REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Rear Door RH)

|

|

| 5. |

CHECK POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Rear Door LH) |

(a) Disconnect the Q6 power window regulator motor assembly (for rear door LH) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B2325 is output (w/ Sliding Roof System) |

A |

| DTC B2325 is output (w/ Panoramic Moon Roof System) |

B |

| DTC B2325 is output (w/o Sliding Roof System and Panoramic Moon Roof System) |

C |

| DTC B2325 is not output |

D |

| B |

.gif) | GO TO STEP 7 |

| C |

.gif) | GO TO STEP 9 |

| D |

.gif) | REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Rear Door LH)

|

|

| 6. |

CHECK SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY) |

(a) Disconnect the V2 sliding roof ECU (sliding roof drive gear sub-assembly) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B2325 is output | A |

|

DTC B2325 is not output |

B |

| A |

.gif) | GO TO STEP 9 |

| B |

.gif) | REPLACE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY)

|

| 7. |

CHECK SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR ASSEMBLY) |

(a) Disconnect the q1 sliding roof ECU (sliding roof drive gear assembly) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B2325 is output | A |

|

DTC B2325 is not output |

B |

| B |

.gif) | REPLACE SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR ASSEMBLY) |

|

| 8. |

CHECK ROOF SUNSHADE ECU (SLIDING ROOF DRIVE GEAR ASSEMBLY) |

(a) Disconnect the q2 roof sunshade ECU (sliding roof drive gear assembly) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B2325 is output | A |

|

DTC B2325 is not output |

B |

| B |

.gif) | REPLACE ROOF SUNSHADE ECU (SLIDING ROOF DRIVE GEAR ASSEMBLY) |

|

| 9. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - EACH ECU) |

(a) Disconnect the 3D instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

3D-25 - Body ground | Always |

10 kΩ or higher |

(c) Disconnect all other connectors in the same circuit.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

3D-25 - Other terminals |

Always | 10 kΩ or higher |

|

Result | Proceed to |

|---|---|

|

OK (w/ Sliding Roof System or Panoramic Moon Roof System) |

A |

| OK (w/o Sliding Roof System and Panoramic Moon Roof System) |

B |

| NG |

C |

| B |

.gif) | GO TO STEP 12 |

| C |

.gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 10. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - EACH ECU) |

(a) Disconnect the 3B instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

3B-17 - Body ground | Always |

10 kΩ or higher |

|

3B-17 - Other terminals |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 11. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

(a) Remove the instrument panel junction block assembly.

Click here

.gif)

.gif)

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

|

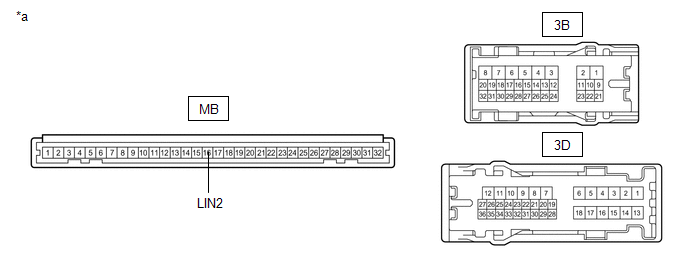

*a | Component without harness connected (Instrument Panel Junction Block Assembly) |

- | - |

(c) Measure the resistance according to the value(s) in the table below.

HINT:

This inspection is to check the LIN communication line in the instrument panel junction block assembly that connects the wire harness to the built-in main body ECU (multiplex network body ECU).

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

| 3D-25 - 3B-3 |

Always | 10 kΩ or higher |

|

MB-16 (LIN2) - Other terminals | Always |

10 kΩ or higher |

| NG | .gif) | REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

|

|

| 12. |

INSPECT MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

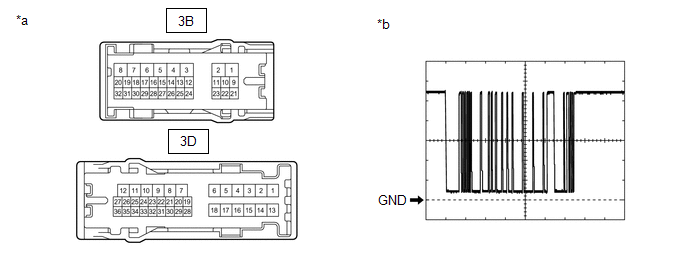

*a | Component without harness connected (Instrument Panel Junction Block Assembly) |

*b | Waveform 1 |

(a) Using a Techstream, check the waveform.

HINT:

This inspection is to check the LIN communication line in the instrument panel junction block assembly that connects the wire harness to the built-in main body ECU (multiplex network body ECU).

OK:

| Tester Connection |

Condition | Tool Setting |

Specified Condition |

|---|---|---|---|

|

3D-25 - Body ground | Ignition switch ON |

2 V/DIV., 200 ms/DIV. | Pulse generation (See waveform 1) |

|

3B-17 - Body ground* |

Ignition switch ON | 2 V/DIV., 200 ms/DIV. |

Pulse generation (See waveform 1) |

- *: w/ Sliding Roof System or Panoramic Moon Roof System

| OK | .gif) | USE SIMULATION METHOD TO CHECK

|

| NG | .gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)

|

| 13. |

CHECK HARNESS AND CONNECTOR (MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY - POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Driver Door)) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

O2-16 (LIN2) - Body ground |

Always | 10 kΩ or higher |

|

O2-16 (LIN2) - Other terminals |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)