Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during shift paddle switch (transmission shift switch assembly) removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision system | |||

|

Memorize steering angle neutral point |

Parking assist monitor system |

| |

|

Panoramic view monitor system |

|

NOTICE:

- Do not remove/install the spiral cable with sensor sub-assembly with the battery connected and the ignition switch ON.

- Do not rotate the spiral cable with sensor sub-assembly without the steering wheel assembly installed, with the battery connected and the ignition switch ON.

- Ensure that the steering wheel assembly is installed and aligned straight when inspecting the steering sensor.

PROCEDURE

1. REMOVE STEERING WHEEL ASSEMBLY

Click here .gif)

2. REMOVE STEERING PAD SWITCH ASSEMBLY

Click here .gif)

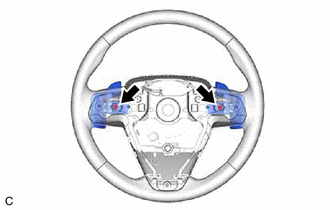

3. REMOVE SHIFT PADDLE SWITCH (TRANSMISSION SHIFT SWITCH ASSEMBLY)

| (a) Remove the 2 screws. |

|

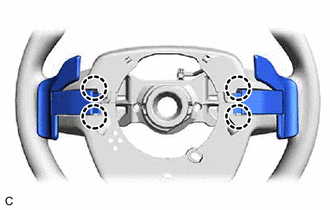

| (b) Disengage the 4 claws. |

|

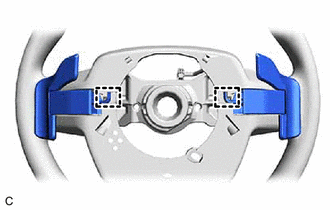

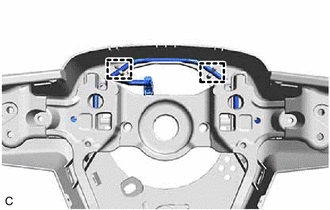

| (c) Disengage the 2 clamps to disconnect the 2 shift paddle switches (transmission shift switch assemblies) from the steering wheel assembly. |

|

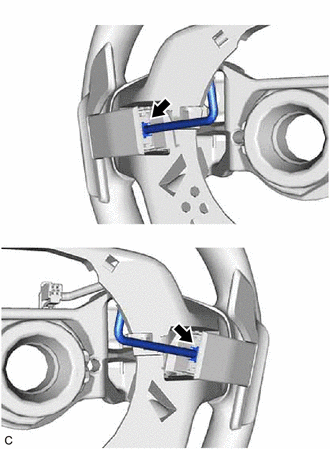

| (d) Disconnect the 2 shift paddle switch (transmission shift switch assembly) connectors to remove the 2 shift paddle switches (transmission shift switch assemblies) from the No. 1 switch wire. |

|

4. REMOVE NO. 1 SWITCH WIRE

HINT:

Perform this procedure only when replacement of the No. 1 switch wire is necessary.

| (a) Disengage the 2 guides and remove the No. 1 switch wire from the steering wheel assembly. |

|