Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during fuel injector assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: When performing learning using the Techstream.

Click here | |||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision system | |||

|

Parking Support Brake System*1 | |||

|

Memorize steering angle neutral point |

Parking assist monitor system |

| |

|

Panoramic view monitor system |

| ||

| Inspection after repair |

|

|

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here .gif)

2. DISCHARGE FUEL SYSTEM PRESSURE

Click here .gif)

3. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here .gif)

4. REMOVE COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

Click here .gif)

5. REMOVE FRONT CENTER UPPER SUSPENSION BRACE SUB-ASSEMBLY

Click here .gif)

6. REMOVE THROTTLE BODY WITH MOTOR ASSEMBLY

Click here .gif)

7. REMOVE V-BANK COVER SUB-ASSEMBLY

Click here .gif)

.gif)

.gif)

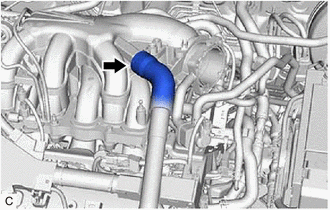

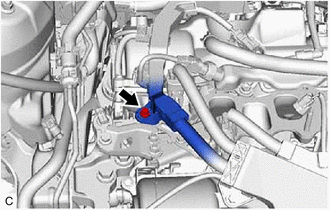

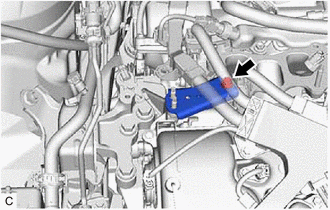

8. DISCONNECT VENTILATION HOSE

| (a) Slide the clip and disconnect the ventilation hose from the intake air surge tank assembly. |

|

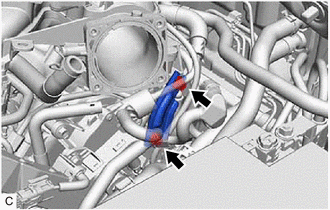

9. DISCONNECT PURGE VALVE (PURGE VSV)

| (a) Disconnect the No. 1 fuel vapor feed hose from the intake air surge tank assembly. |

|

(b) Remove the bolt and disconnect the purge valve (purge VSV) from the intake air surge tank assembly.

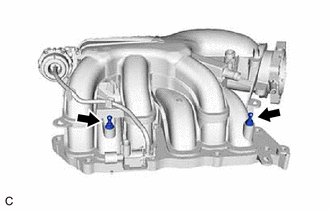

10. REMOVE NO. 2 SURGE TANK STAY

| (a) Remove the 2 bolts and No. 2 surge tank stay from the intake air surge tank assembly and camshaft housing RH. |

|

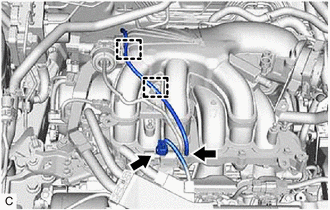

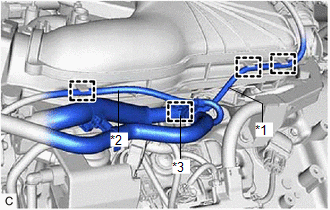

11. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

| (a) Disconnect the vacuum switching valve (for ACIS) connector. |

|

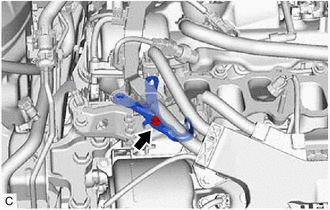

(b) Disengage the 2 clamps to disconnect the vacuum hose sub-assembly from the intake air surge tank assembly.

| (c) Disengage the 2 clamps to disconnect the vacuum hose sub-assembly from the intake air surge tank assembly. |

|

(d) Disengage the clamp to disconnect the vacuum hose from the intake air surge tank assembly.

(e) Disengage the clamp to disconnect the No. 2 air tube from the intake air surge tank assembly.

(f) Remove the 5 bolts, 2 nuts and intake air surge tank assembly from the intake manifold.

.png) |

Bolt |

.png) |

Nut |

(g) Remove the plug from the intake air surge tank assembly.

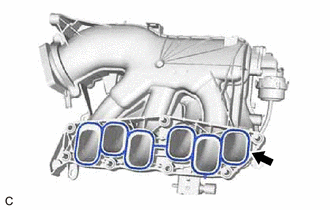

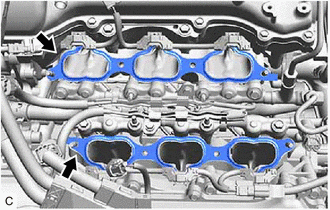

12. REMOVE AIR SURGE TANK TO INTAKE MANIFOLD GASKET

| (a) Remove the air surge tank to intake manifold gasket from the intake air surge tank assembly. |

|

13. REMOVE NO. 1 V-BANK COVER BRACKET

HINT:

Perform this procedure only when replacement of the No. 1 V-bank cover bracket is necessary.

| (a) Remove the 2 No. 1 V-bank cover brackets from the intake air surge tank assembly. |

|

14. REMOVE NO. 2 ENGINE MOUNTING STAY RH

| (a) Remove the bolt and disconnect the wire harness clamp from the wire harness clamp bracket. |

|

| (b) Remove the bolt and separate the wire harness clamp bracket from the No. 2 engine mounting stay RH. |

|

(c) Remove the bolt, 2 nuts and No. 2 engine mounting stay RH from the engine mounting insulator sub-assembly RH.

.png) |

Bolt |

.png) |

Nut |

| (d) Remove the bolt and No. 2 engine mounting stay RH from the intake manifold and front No.1 engine mounting bracket LH. |

|

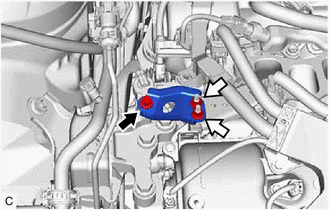

15. DISCONNECT FUEL TUBE SUB-ASSEMBLY

Click here

.gif)

16. REMOVE FUEL DELIVERY PIPE WITH SENSOR ASSEMBLY

Click here .gif)

17. REMOVE NO. 1 DELIVERY PIPE SPACER

Click here .gif)

18. REMOVE INJECTOR VIBRATION INSULATOR

Click here .gif)

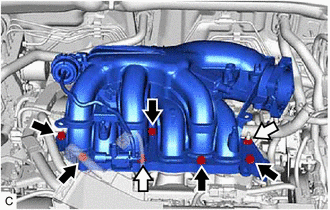

19. REMOVE INTAKE MANIFOLD

(a) Remove the 4 bolts, 4 nuts and intake manifold from the cylinder head sub-assembly.

.png) |

Bolt |

.png) |

Nut |

20. REMOVE NO. 1 INTAKE MANIFOLD TO HEAD GASKET

| (a) Remove the 2 No. 1 intake manifold to head gaskets from each cylinder head sub-assembly. |

|

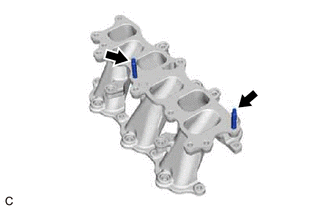

21. REMOVE STUD BOLT

HINT:

If a stud bolt is deformed or the threads are damaged, replace it.

| (a) Using an E6 "TORX" socket wrench, remove the 2 stud bolts from the intake manifold. |

|