Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rack and pinion power steering gear assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: w/ Smart Key System

*2: w/o Smart Key System *3: When the ECM is replaced with a new one, reset memory is unnecessary. | |||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision system | |||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

| |

|

Panoramic view monitor system |

| ||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on | for A25A-FKS:

for 2GR-FKS:

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

w/ Smart Key System: w/o Smart Key System:

| |

| Inspection After Repair |

| for A25A-FKS:

for 2GR-FKS:

|

|

Replacement of automatic transaxle assembly |

|

| for UB80E Initialization:

for UB80E Registration:

for UA80E Initialization:

for UA80E Registration:

for UB80F Initialization:

for UB80F Registration:

|

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

| ||

| Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

| ||

| Automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

for UB80E: for UA80E:

for UB80F:

|

|

Replacement of ECM*1 |

Code registration (Smart key System (for Start Function) |

|

|

|

Replacement of ECM*2 |

Code registration (Immobiliser system (w/o Smart Key System)) |

|

|

|

Front wheel alignment adjustment |

|

| w/ Electric Parking Brake System:

w/o Electric Parking Brake System:

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

for Initialization: for Calibration: |

| Panoramic view monitor system |

for Initialization: for Calibration: | |

|

Rack and pinion power steering gear assembly |

|

|

|

PROCEDURE

1. PRECAUTION

(a) When handling the rack and pinion power steering gear assembly:

(1) Do not subject the rack and pinion power steering gear assembly (especially the motor and torque sensor) to any impact. Replace the rack and pinion power steering gear assembly with a new one if subjected to a strong impact.

(2) Do not pull the wire harness when moving the rack and pinion power steering gear assembly.

(3) When the rack and pinion power steering gear assembly has been replaced, perform torque sensor zero point calibration.

Click here .gif)

(b) When disconnecting or reconnecting the connectors:

(1) Before disconnecting connectors related to the power steering system, turn the ignition switch to ON, center the steering wheel, turn the ignition switch off, and then disconnect the connectors.

(2) Before reconnecting connectors related to the power steering system, ensure that the ignition switch is off. Then center the steering wheel and turn the ignition switch to ON.

NOTICE:

Do not turn the ignition switch to ON when the steering wheel is not centered.

(3) If the above operations are not carried out properly, the steering center point (zero point) will deviate, which may lead to a difference in steering effort between turning right and left.

HINT:

If there is a difference in steering effort between turning right and left, perform torque sensor zero point calibration.

Click here .gif)

2. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

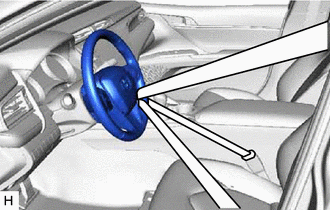

3. SECURE STEERING WHEEL

| (a) Secure the steering wheel with the seat belt in order to prevent rotation. HINT: This operation is useful to prevent damage to the spiral cable. |

|

4. REMOVE FRONT WHEELS

Click here

.gif)

5. REMOVE FRONT WHEEL OPENING EXTENSION PAD LH

for A25A-FKS: Click here .gif)

.gif)

for 2GR-FKS: Click here

.gif)

.gif)

.gif)

6. REMOVE FRONT WHEEL OPENING EXTENSION PAD RH

for A25A-FKS: Click here .gif)

.gif)

for 2GR-FKS: Click here

.gif)

.gif)

.gif)

7. REMOVE NO. 1 ENGINE UNDER COVER

for A25A-FKS: Click here .gif)

.gif)

for 2GR-FKS: Click here

.gif)

.gif)

.gif)

8. REMOVE NO. 2 ENGINE UNDER COVER ASSEMBLY (for A25A-FKS)

Click here .gif)

.gif)

9. REMOVE REAR ENGINE UNDER COVER LH (for 2GR-FKS)

Click here .gif)

.gif)

.gif)

10. REMOVE REAR ENGINE UNDER COVER RH (for 2GR-FKS)

Click here .gif)

.gif)

.gif)

11. SEPARATE STEERING INTERMEDIATE SHAFT ASSEMBLY

| (a) Remove the bolt and slide the steering intermediate shaft assembly. NOTICE: Do not separate the steering intermediate shaft assembly from the rack and pinion power steering gear assembly. |

|

(b) Put matchmarks on the rack and pinion power steering gear assembly and steering intermediate shaft assembly.

(c) Separate the steering intermediate shaft assembly from the rack and pinion power steering gear assembly.

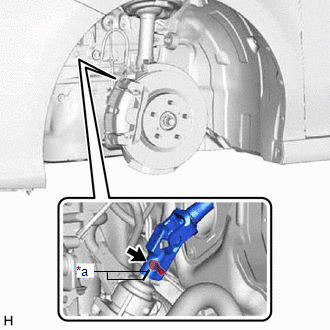

12. SEPARATE TIE ROD ASSEMBLY LH

| (a) Remove the cotter pin and nut. |

|

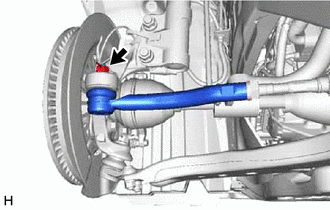

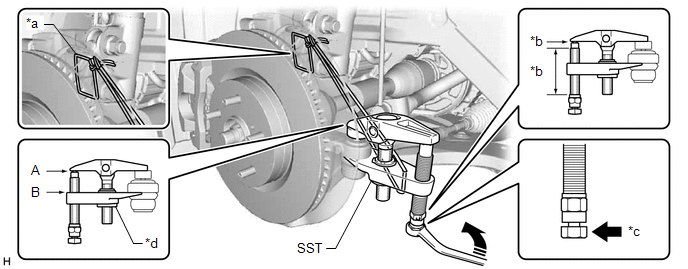

| (b) Install SST to the tie rod assembly LH as shown in the illustration. SST: 09960-20010 09961-02060 NOTICE: Make sure that the upper ends of the tie rod assembly LH and SST are aligned. |

|

(c) Using SST, separate the tie rod assembly LH from the steering knuckle LH as shown in the illustration.

SST: 09960-20010

09961-02010

|

*a | String |

*b | Molybdenum Grease Application Area |

|

*c | Place wrench here |

*d | Center Nut |

.png) |

Turn | - |

- |

CAUTION:

Apply molybdenum grease to the threads and end of the SST bolt.

NOTICE:

- Be sure to tighten the string firmly to secure SST to the steering knuckle LH to prevent SST from falling off.

- Install SST with the center nut so that (A) and (B) shown in the illustration are parallel. Otherwise, the ball joint dust cover may be damaged.

- Be sure to place the wrench on the part shown in the illustration.

- Do not damage the front disc brake dust cover.

- Do not damage the ball joint dust cover.

- Do not damage the steering knuckle LH.

13. SEPARATE TIE ROD ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

14. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

for A25A-FKS: Click here

.gif)

.gif)

for 2GR-FKS: Click here

.gif)

.gif)

.gif)

15. REMOVE STEERING GEAR HEAT INSULATOR (for A25A-FKS)

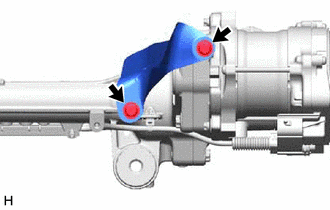

| (a) Remove the 2 bolts and steering gear heat insulator from the rack and pinion power steering gear assembly. |

|

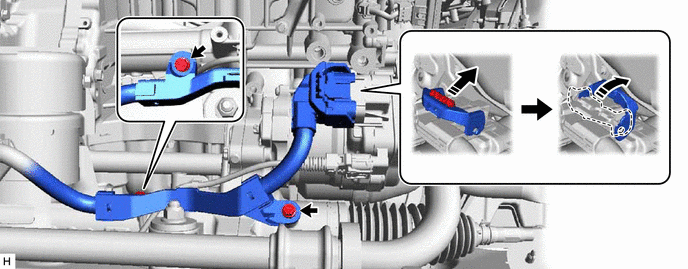

16. DISCONNECT WIRE HARNESS

(a) Disconnect the wire harness connector from the rack and pinion power steering gear assembly.

HINT:

Release the lock before rotating the lock lever.

(b) Remove the 2 bolts and separate the wire harness from the rack and pinion power steering gear assembly.

17. REMOVE FUEL DELIVERY GUARD (for A25A-FKS)

Click here

.gif)

.gif)

18. REMOVE FUEL PUMP PROTECTOR (for AWD)

Click here .gif)

.gif)

19. INSTALL ENGINE HANGER

for A25A-FKS: Click here .gif)

.gif)

for 2GR-FKS: Click here

.gif)

.gif)

.gif)

20. REMOVE FRONT FRAME ASSEMBLY

Click here .gif)

21. REMOVE FRONT STABILIZER BAR WITH BRACKET (for A25A-FKS)

| (a) Remove the 2 bolts and separate the front No. 1 stabilizer bracket LH from the front frame assembly. |

|

| (b) Remove the 2 bolts and separate the front No. 1 stabilizer bracket RH from the front frame assembly. |

|

(c) Remove the front stabilizer bar with the 2 front stabilizer links, front No. 1 stabilizer bracket LH, front No. 1 stabilizer bracket RH and 2 front No. 1 stabilizer bar bushings from the front frame assembly.

22. REMOVE FRONT STABILIZER BAR WITH BRACKET (for 2GR-FKS)

| (a) Remove the 2 bolts and separate the front No. 1 stabilizer bracket LH from the front frame assembly. |

|

(b) Remove the 2 bolts and separate the front No. 1 stabilizer bracket RH from the front frame assembly.

HINT:

Perform the same procedure as for the LH side.

(c) Remove the front stabilizer bar with 2 front stabilizer links, front No. 1 stabilizer bracket LH, front No. 1 stabilizer bracket RH and 2 front No. 1 stabilizer bar bushings from the front frame assembly.

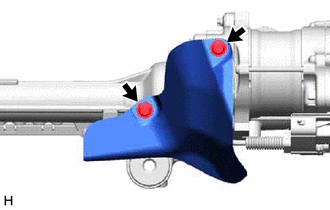

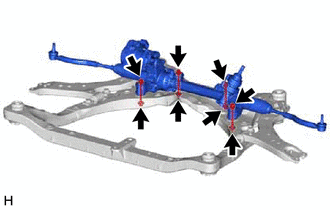

23. REMOVE RACK AND PINION POWER STEERING GEAR ASSEMBLY

| (a) Remove the 4 bolts, 4 nuts and rack and pinion power steering gear assembly from the front frame assembly. NOTICE: Because the nut has its own stopper, do not turn the nut. Loosen the bolt with the nut secured. |

|

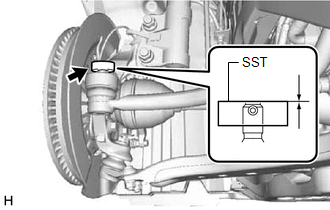

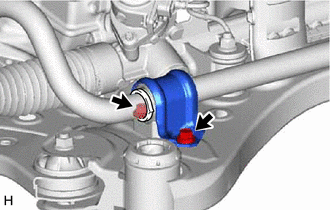

24. SECURE RACK AND PINION POWER STEERING GEAR ASSEMBLY

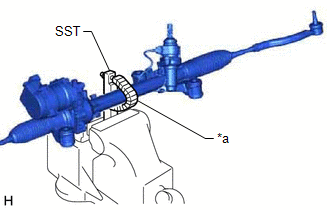

| (a) Using SST, secure the rack and pinion power steering gear assembly in a vise. SST: 09612-00012 HINT: Wrap SST with protective tape before use. |

|

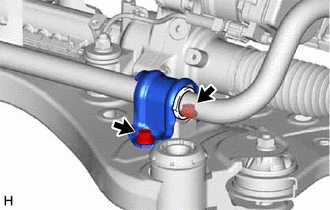

25. REMOVE TIE ROD ASSEMBLY LH

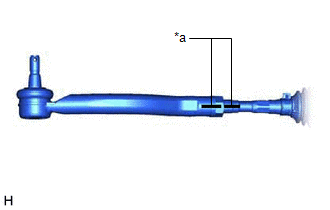

| (a) Put matchmarks on the tie rod assembly LH and rack and pinion power steering gear assembly. |

|

(b) Remove the tie rod assembly LH and lock nut.

26. REMOVE TIE ROD ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

27. REMOVE STEERING GEAR HEAT INSULATOR (for 2GR-FKS)

| (a) Remove the 2 bolts and steering gear heat insulator from the rack and pinion power steering gear assembly. |

|