Toyota Camry (XV70): Components

COMPONENTS

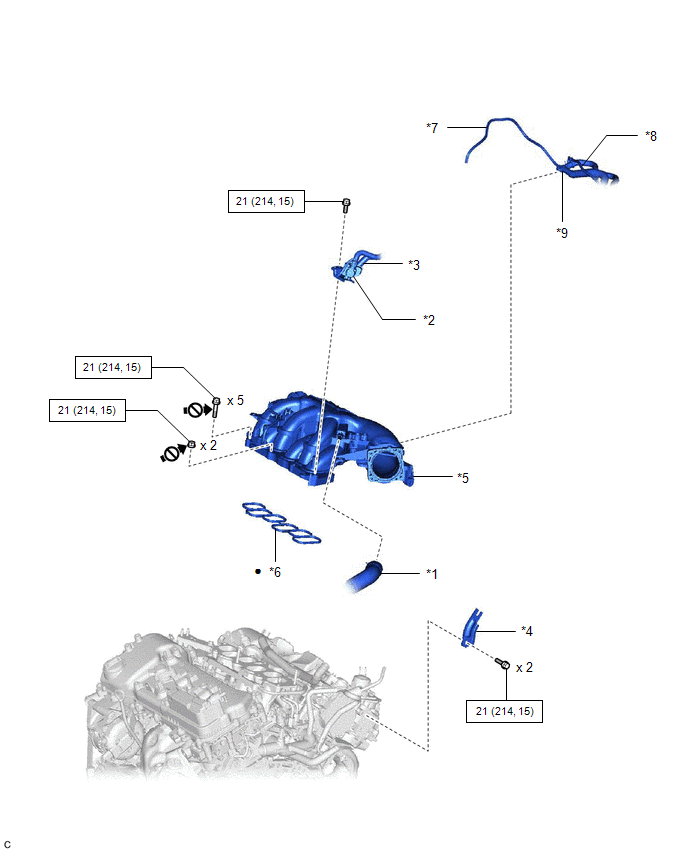

ILLUSTRATION

|

*1 | VENTILATION HOSE |

*2 | PURGE VALVE (PURGE VSV) |

|

*3 | NO. 1 FUEL VAPOR FEED HOSE |

*4 | NO. 2 SURGE TANK STAY |

|

*5 | INTAKE AIR SURGE TANK ASSEMBLY |

*6 | AIR SURGE TANK TO INTAKE MANIFOLD GASKET |

|

*7 | VACUUM HOSE SUB-ASSEMBLY |

*8 | VACUUM HOSE |

|

*9 | NO. 2 AIR TUBE |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

.png) |

Do not apply lubricants (to the threaded parts) |

- | - |

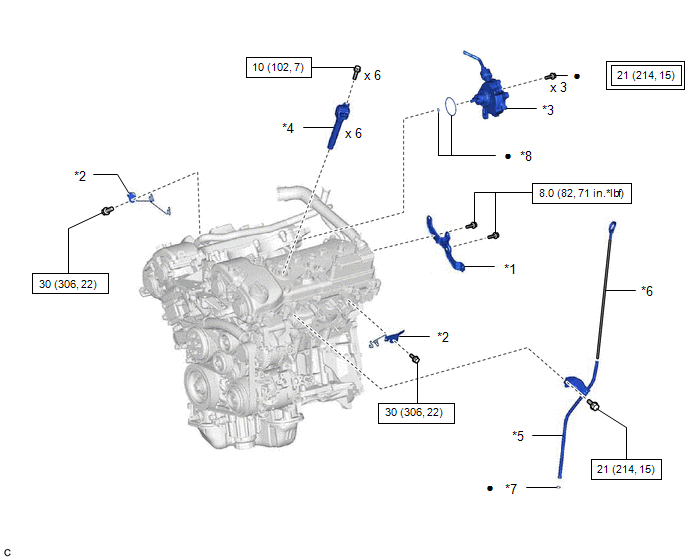

ILLUSTRATION

|

*1 | WATER FILLER BRACKET |

*2 | WIRE HARNESS CLAMP BRACKET |

|

*3 | VACUUM PUMP ASSEMBLY |

*4 | IGNITION COIL ASSEMBLY |

|

*5 | ENGINE OIL LEVEL DIPSTICK GUIDE |

*6 | ENGINE OIL LEVEL DIPSTICK |

|

*7 | ENGINE OIL LEVEL DIPSTICK GUIDE O-RING |

*8 | O-RING |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

★ | Precoated part |

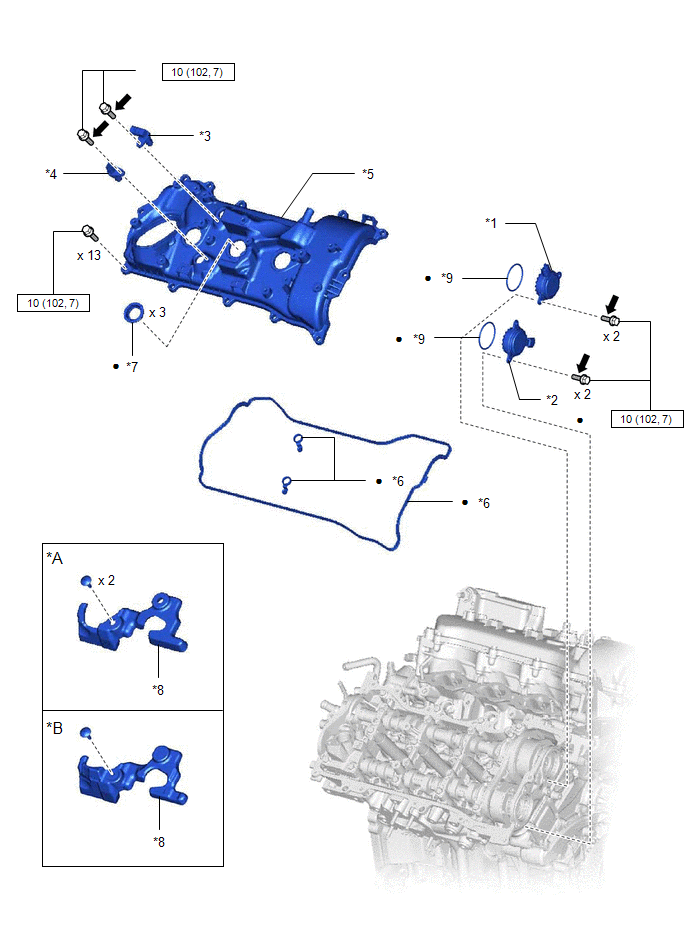

ILLUSTRATION

|

*A | Type A |

*B | Type B |

|

*1 | CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 1) |

*2 | CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 1) |

|

*3 | VVT SENSOR (for Intake Side of Bank 1) |

*4 | VVT SENSOR (for Exhaust Side of Bank 1) |

|

*5 | CYLINDER HEAD COVER SUB-ASSEMBLY |

*6 | CYLINDER HEAD COVER GASKET |

|

*7 | SPARK PLUG TUBE GASKET |

*8 | NO. 1 ENGINE COVER SUB-ASSEMBLY |

|

*9 | O-RING |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

.png) |

Adhesive 1324 | ★ |

Precoated part |

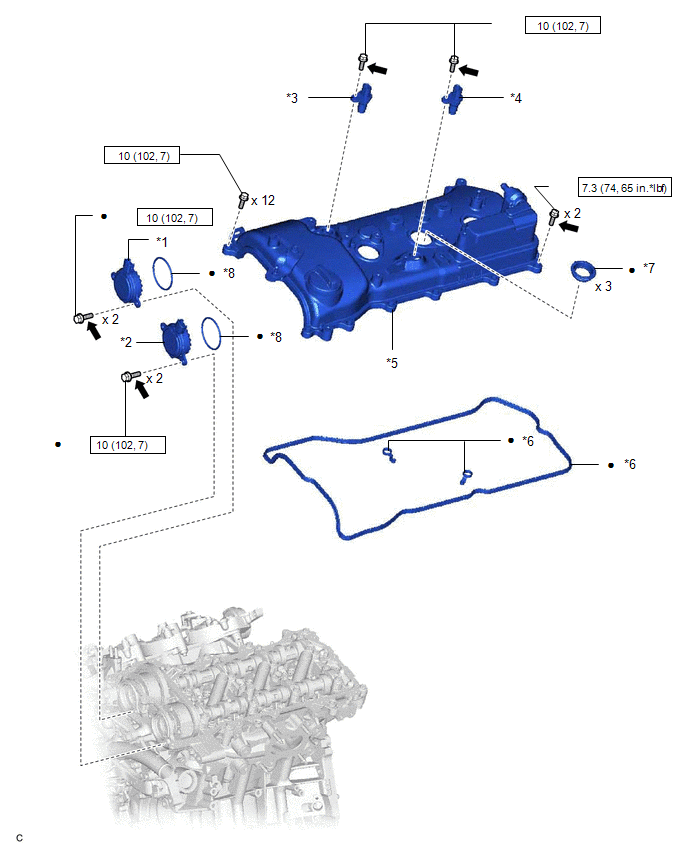

ILLUSTRATION

|

*1 | CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 2) |

*2 | CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 2) |

|

*3 | VVT SENSOR (for Intake Side of Bank 2) |

*4 | VVT SENSOR (for Exhaust Side of Bank 2) |

|

*5 | CYLINDER HEAD COVER SUB-ASSEMBLY LH |

*6 | NO. 2 CYLINDER HEAD COVER GASKET |

|

*7 | SPARK PLUG TUBE GASKET |

*8 | O-RING |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

.png) |

Adhesive 1324 | ★ |

Precoated part |

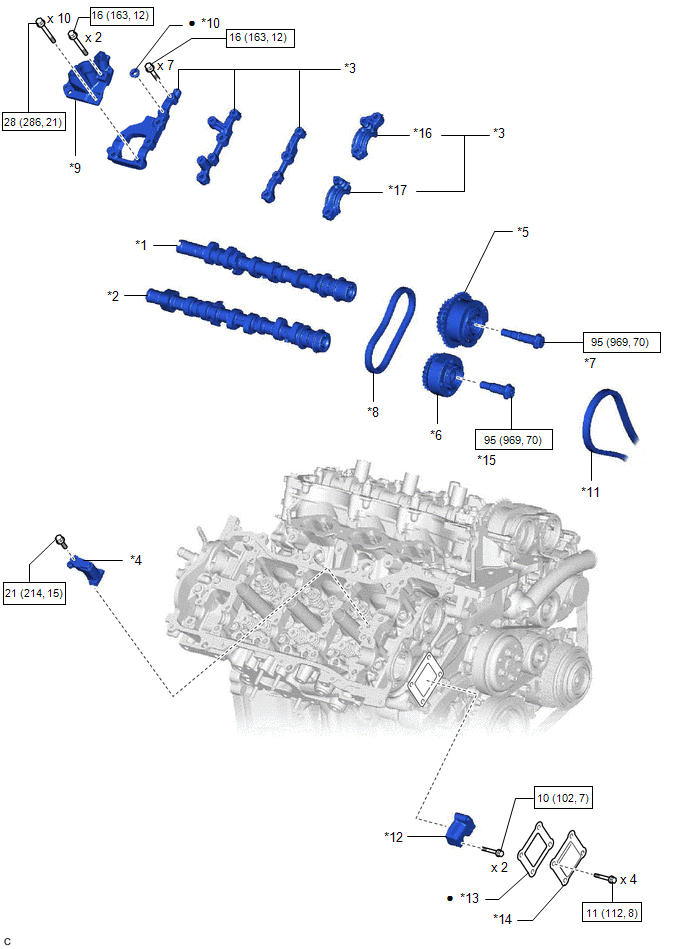

ILLUSTRATION

|

*1 | CAMSHAFT |

*2 | NO. 2 CAMSHAFT |

|

*3 | CAMSHAFT BEARING CAP (for Bank 1) |

*4 | NO. 2 CHAIN TENSIONER ASSEMBLY |

|

*5 | CAMSHAFT TIMING GEAR ASSEMBLY (for Bank 1) |

*6 | CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY (for Bank 1) |

|

*7 | CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 1) |

*8 | NO. 2 CHAIN SUB-ASSEMBLY (for Bank 1) |

|

*9 | FUEL PUMP LIFTER HOUSING |

*10 | CAMSHAFT BEARING CAP OIL HOLE GASKET |

|

*11 | CHAIN SUB-ASSEMBLY (for Bank 1) |

*12 | NO. 1 CHAIN TENSIONER ASSEMBLY |

|

*13 | TIMING CHAIN COVER GASKET |

*14 | TIMING CHAIN COVER PLATE |

|

*15 | CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 1) |

*16 | NO. 1 CAMSHAFT BEARING CAP |

|

*17 | NO. 2 CAMSHAFT BEARING CAP |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

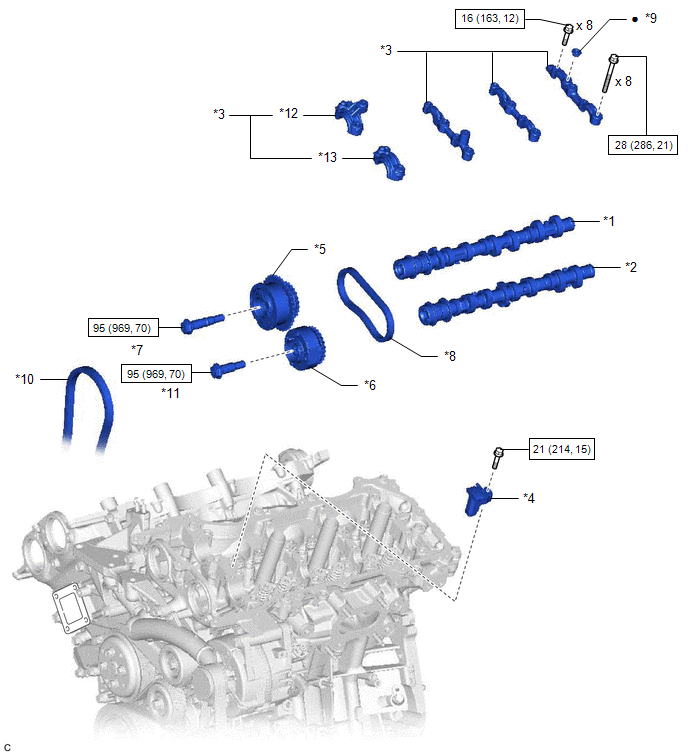

ILLUSTRATION

|

*1 | NO. 3 CAMSHAFT SUB-ASSEMBLY |

*2 | NO. 4 CAMSHAFT SUB-ASSEMBLY |

|

*3 | CAMSHAFT BEARING CAP (for Bank 2) |

*4 | NO. 3 CHAIN TENSIONER ASSEMBLY |

|

*5 | CAMSHAFT TIMING GEAR ASSEMBLY (for Bank 2) |

*6 | CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY (for Bank 2) |

|

*7 | CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 2) |

*8 | NO. 2 CHAIN SUB-ASSEMBLY (for Bank 2) |

|

*9 | CAMSHAFT BEARING CAP OIL HOLE GASKET LH |

*10 | CHAIN SUB-ASSEMBLY (for Bank 2) |

|

*11 | CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 2) |

*12 | NO. 3 CAMSHAFT BEARING CAP |

|

*13 | NO. 4 CAMSHAFT BEARING CAP |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |