Toyota Camry (XV70): Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during engine unit removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: When the ECM is replaced with a new one, reset memory is unnecessary. | |||

| Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision System | |||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

| |

|

Panoramic view monitor system |

| ||

|

Replacement of ECM | Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

| |

| Inspection After Repair |

|

|

|

Replacement of automatic transaxle assembly |

|

|

|

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

| ||

| Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

| ||

| Replacement of ECM |

Code registration |

|

|

|

Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Replacement of front bumper assembly |

Front television camera view adjustment |

Panoramic view monitor system |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

| ||

| Front wheel alignment adjustment |

|

|

|

PROCEDURE

1. REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD

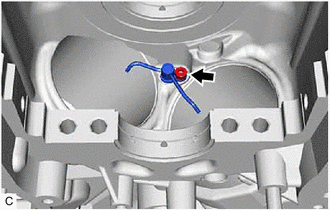

(a) Check that the matchmarks on the connecting rod sub-assembly and connecting rod cap are aligned.

HINT:

The matchmarks on the connecting rod sub-assembly and connecting rod cap are guides for correct reassembly.

(b) Remove the 2 connecting rod bolts.

.png) |

Front of Engine |

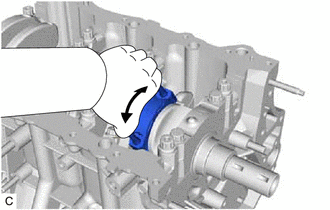

| (c) Using the 2 removed connecting rod bolts, remove the connecting rod cap and lower connecting rod bearing by wiggling the connecting rod cap right and left. HINT: Keep the lower connecting rod bearing installed to the connecting rod cap. |

|

| (d) Using a ridge reamer, remove all of the carbon from the top of the cylinder. |

|

(e) Push the piston, connecting rod sub-assembly and upper connecting rod bearing through the top of the cylinder block sub-assembly.

HINT:

- Keep the connecting rod bearing, connecting rod sub-assembly and connecting rod cap together.

- Arrange the removed parts in such a way that they can be reinstalled to their original locations.

2. REMOVE CONNECTING ROD BEARING

(a) Remove the connecting rod bearings from the connecting rod sub-assembly and connecting rod cap.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

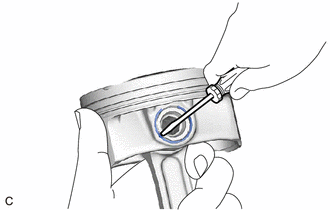

3. REMOVE PISTON RING SET

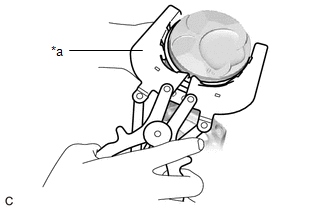

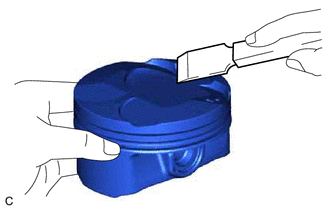

| (a) Using a piston ring expander, remove the No. 1 compression ring and No. 2 compression ring. |

|

(b) Remove the oil ring expander and 2 side rails by hand.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

4. REMOVE PISTON

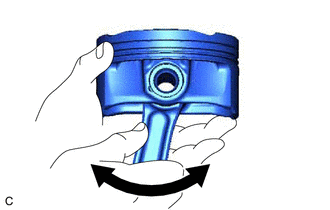

| (a) Check the fitting condition between the piston and piston pin. (1) Try to move the piston back and forth on the piston pin. HINT: If abnormal movement is felt, replace the piston and piston pin as a set. |

|

(b) Remove the connecting rod sub-assembly from the piston.

(1) Using a screwdriver, pry out the piston pin hole snap ring (front side).

NOTICE:

- Do not remove the piston pin hole snap ring (rear side) unless it has to be replaced.

- Be careful not to damage the piston when removing the piston pin hole snap ring (rear side).

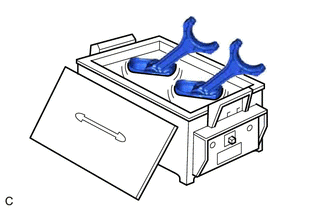

| (2) Gradually heat the piston to approximately 80°C (176°F). CAUTION: Be sure to wear protective gloves. |

|

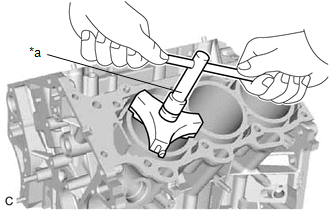

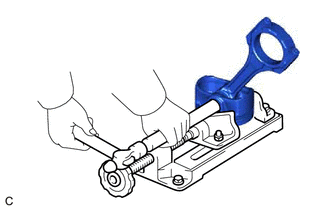

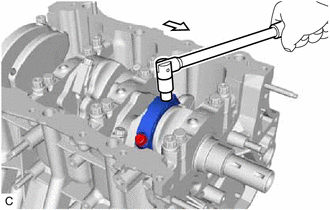

| (3) Using a brass bar and a hammer, lightly tap out the piston pin and remove the connecting rod sub-assembly. HINT:

|

|

| (c) Using a gasket scraper, remove any carbon from the piston top. NOTICE: Be careful not to scratch the piston. |

|

| (d) Using a groove cleaning tool or a broken ring, clean the piston ring grooves. |

|

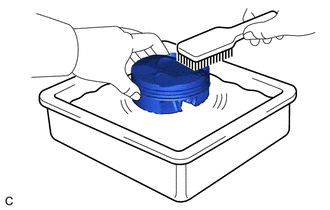

| (e) Using solvent and a brush, thoroughly clean the piston. NOTICE: Do not use a wire brush. |

|

5. REMOVE CRANKSHAFT

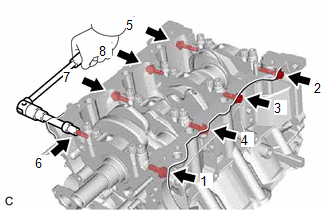

| (a) Uniformly loosen and remove the 8 crankshaft bearing cap set bolts and 8 seal washers in several steps in the order shown in the illustration. |

|

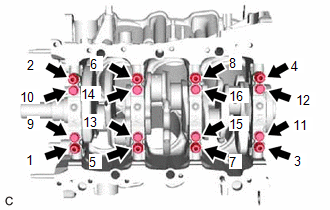

| (b) Uniformly loosen the 16 crankshaft bearing cap set bolts in several steps in the order shown in the illustration. |

|

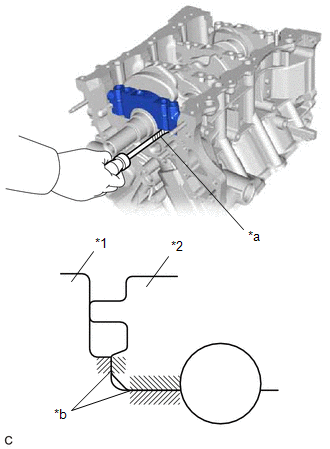

| (c) Using a screwdriver with its tip wrapped with protective tape, pry out the crankshaft bearing caps. Remove the 4 crankshaft bearing caps and 4 lower crankshaft bearings as a set. NOTICE:

|

|

(d) Remove the crankshaft.

6. REMOVE CRANKSHAFT BEARING

(a) Remove the upper crankshaft bearings and lower crankshaft bearings.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

7. REMOVE CRANKSHAFT THRUST WASHER SET

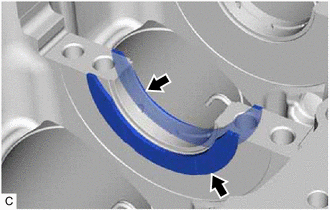

| (a) Remove the crankshaft thrust washer set from the cylinder block sub-assembly. |

|

8. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

| (a) Using a 5 mm hexagon socket wrench, remove the 3 bolts and 3 No. 1 oil nozzle sub-assemblies. |

|

(b) Check the 3 No. 1 oil nozzle sub-assemblies for damage or clogging.

HINT:

If there is damage or clogs, replace the No. 1 oil nozzle sub-assembly.

.gif)