Toyota Camry (XV70): High Temperature Adjustment

HIGH TEMPERATURE ADJUSTMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during automatic transaxle fluid replacement are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

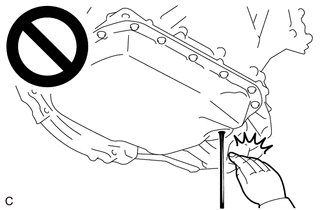

CAUTION:

- Be careful not to burn yourself when the temperature of the automatic transaxle fluid is high.

- To prevent injury due to contact with an operating V-ribbed belt or cooling fan, keep your hands and clothing away from the V-ribbed belt and cooling fans when working in the engine compartment with the engine running or the engine switch on (IG).

PROCEDURE

1. ADJUST AUTOMATIC TRANSAXLE FLUID LEVEL AT HIGH TEMPERATURE

(a) Warm up the engine and then turn the engine switch off.

(b) Check the automatic transaxle fluid temperature.

(1) Connect the Techstream to the DLC3 with the engine switch off.

(2) Turn the engine switch on (IG) and turn the Techstream on.

NOTICE:

To reduce load, make sure that all electrical systems, such as the air conditioning, lighting system, electric fan and audio system are off.

(3) Enter the following menus: Powertrain / Transmission / Data List / Engine Speed and A/T Oil Temperature No.1.

Powertrain > Transmission > Data List|

Tester Display |

|---|

| Engine Speed |

|

A/T Oil Temperature No.1 |

NOTICE:

- If the automatic transaxle fluid temperature tends to decrease when the automatic transaxle fluid temperature is between 85

.gif)