Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

1. INSPECT CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY

HINT:

Use the same procedure for the intake side and exhaust side.

(a) Check the resistance.

| (1) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

1 - 2 | 0 °C (32 °F) |

5.3 to 6.3 Ω | |

20 °C (68 °F) | 5.8 to 6.8 Ω | |

40 °C (104 °F) | 6.2 to 7.4 Ω |

If the result is not as specified, replace the camshaft timing oil control solenoid assembly. |

|

|

*a | Component without harness connected

(Camshaft Timing Oil Control Solenoid Assembly) | | |

(b) Stroke Amount Inspection

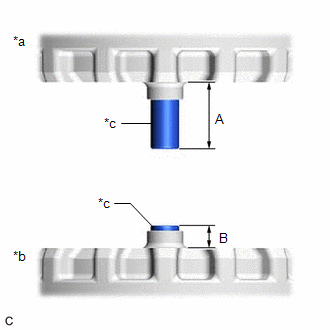

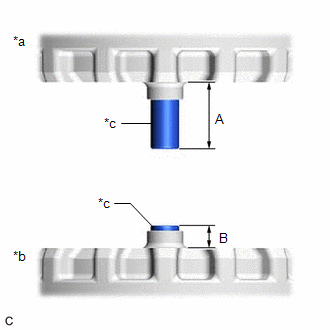

| (1) Using vernier calipers, measure length (A) and (B) with the shaft of the camshaft timing oil control solenoid assembly set in the respective positions shown in the illustration.

NOTICE: Do not apply battery voltage to the terminals of the camshaft timing oil control solenoid assembly.

HINT: If the shaft does not extend under its own weight, extend the shaft with your fingers. |

|

|

*a | Shaft Side Facing Down | |

*b | Shaft Side Facing Up | |

*c | Shaft | | |

(2) Calculate the stroke amount based on the difference of length (A) and (B).

Standard:

6.5 mm (0.256 in.) or more

HINT:

Stroke amount = length (A) - length (B)

If the value is not as specified, replace the camshaft timing oil control solenoid assembly.

READ NEXT:

INSTALLATION PROCEDURE 1. INSTALL CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 2)

(a) Apply engine oil to a new O-ring and install it to the camshaft timing oil control

COMPONENTS ILLUSTRATION

*1 FRONT FENDER APRON SEAL RH

*2 V-BANK COVER SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf): Specified torque

- - ILLUSTRATION

*1

SEE MORE:

DESCRIPTION When the electric parking brake switch is pulled, a lock request signal is sent from the skid control ECU (brake actuator assembly) to the parking brake actuator assembly. When the electric parking brake switch is pushed, a release request signal is sent from the skid control ECU (brake

REMOVAL CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during transmission valve body assembly removal/installation are shown below. Necessary Procedures After Part