Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL SENDER GAUGE ASSEMBLY

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

(a) Check that the float moves smoothly between F and E.

(b) Check the fuel sender gauge assembly voltage.

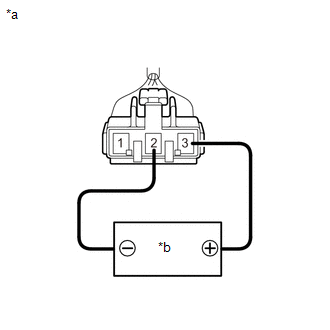

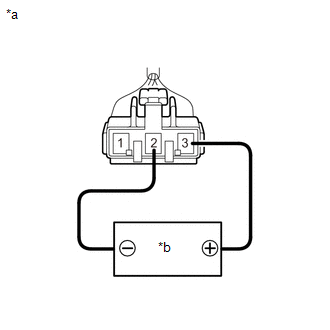

| (1) Apply 5 V between terminals 2 and 3.

NOTICE:

- Be careful when connecting the leads, as the fuel sender gauge assembly may be damaged if the leads are connected to the wrong terminals.

- Do not apply more than 6 V to terminals 2 or 3.

HINT: If a stable power supply is not available, connect 4 nickel-metal hydride batteries (1.2 V each) or equivalent in series. |

|

|

*a | Component without harness connected

(Fuel Sender Gauge Assembly) | |

*b | Voltage Applied between Terminals | | |

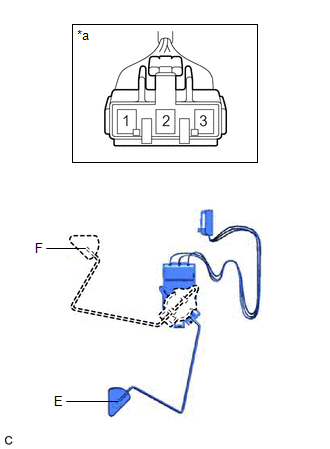

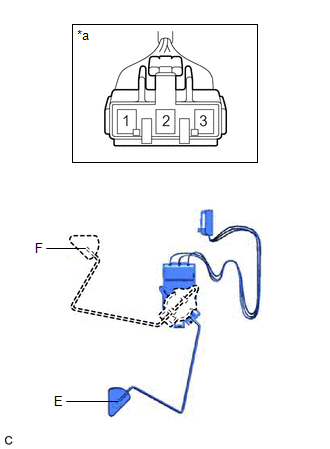

| (2) Measure the voltage according to the value(s) in the table below.

Standard Voltage: |

Tester Connection | Float Level |

Specified Condition | |

1 - 2 | F |

4.255 to 4.605 V* | |

Between F and E | 0.345 to 4.605 V* (Gradually changes) | |

E | 0.345 to 0.695 V* |

*: The output voltage changes depending on the voltage applied to the terminals.

Output voltage (F) = (0.851 x Voltage applied to terminals) to (0.921 x Voltage applied to terminals)

Output voltage (E) = (0.069 x Voltage applied to terminals) to (0.139 x Voltage applied to terminals)

If the result is not as specified, replace the fuel sender gauge assembly. |

|

|

*a | Component without harness connected

(Fuel Sender Gauge Assembly) | | |

READ NEXT:

INSTALLATION PROCEDURE 1. INSTALL FUEL SENDER GAUGE ASSEMBLY

(a) Engage the claw to install the fuel sender gauge assembly to the fuel suction tube with pump and gauge assembly.

NOTICE: Be careful

COMPONENTS ILLUSTRATION

*1 FUEL SENDER GAUGE ASSEMBLY

*2 FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY

REMOVAL CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during fu

SEE MORE:

REMOVAL PROCEDURE 1. REMOVE THROTTLE BODY WITH MOTOR ASSEMBLY

Click here 2. REMOVE NO. 2 SURGE TANK STAY

Click here

3. SEPARATE ENGINE WIRE

(a) Remove the 2 bolts and separate the engine wire.

(b) Remove the bolt and separate the earth wire.

4

The following is a French explanation of SRS airbag instructions

extracted from the SRS airbag section in this manual.

See the SRS airbag section for more detailed SRS airbag instructions

in English.

◆ Coussins gonflables frontaux SRS

Coussin gonflable conducteur/coussin gonflable du pas