Toyota Camry (XV70): Installation

INSTALLATION

CAUTION / NOTICE / HINT

CAUTION:

The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop or the engine assembly with transaxle may fall off the engine lifter.

PROCEDURE

1. INSTALL TORQUE CONVERTER ASSEMBLY

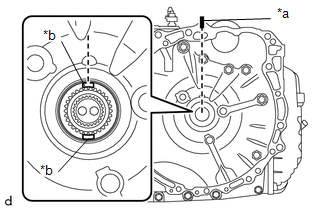

| (a) Set the key at the top of the front oil pump drive gear and put a matchmark on the transaxle housing. |

|

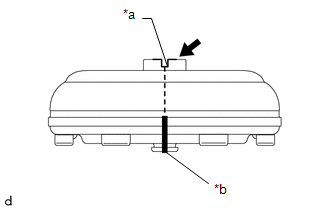

(b) Apply MP grease to place a matchmark on the torque converter assembly so that the position of its groove is clearly indicated.

|

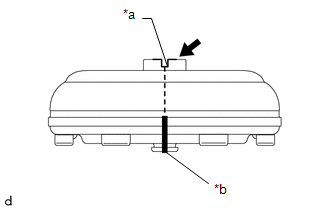

*a | Groove |

|

*b | Matchmark |

.png) |

MP Grease |

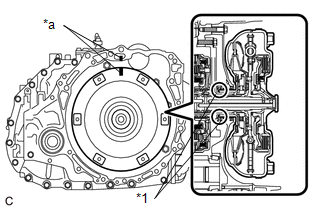

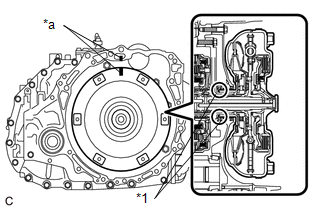

| (c) Align the matchmark on the housing with the one on the torque converter assembly and engage the splines of the input shaft with the turbine runner splines.

NOTICE:

- Install the torque converter assembly to the input shaft while keeping it horizontal.

- Do not damage the front oil pump oil seal.

|

|

|

*1 | Front Oil Pump Oil Seal | |

*a | Matchmark | | |

| (d) Rotate the torque converter assembly approximately 180 |

READ NEXT:

COMPONENTS ILLUSTRATION

*1 REAR ENGINE UNDER COVER LH

*2 FRONT FENDER APRON SEAL LH

*3 NO. 1 ENGINE UNDER COVER

*4 FRONT WHEEL OPENING EXTENSION PAD LH

*5

REPLACEMENT CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced duri

SEE MORE:

OPERATION CHECK CHECK TIRE PRESSURE WARNING SYSTEM FUNCTION

(a) Using the Data List, check that the current tire pressure is normal.

Click here

(1) Slowly reduce the tire pressure of the front or rear tires and check that the tire pressure on the Data List changes.

(2) Further reduce

DESCRIPTION Based on signals from the transmission revolution sensors (NT and NC), the actual gear is detected.

The ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical malfunctions of the solenoid valves, transmission valve body assembly and automatic transa

.png)