Toyota Camry (XV70): On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. OPERATION CHECK

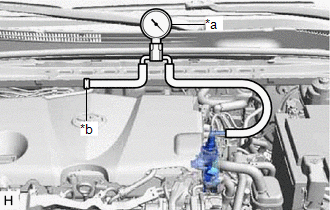

(a) Slide the clip and disconnect the union to check valve hose from the vacuum pump assembly.

| (b) Connect the hose of the vacuum gauge to the vacuum pump assembly. |

|

(c) Start the engine and warm it up for more than 2 minutes.

(d) With the engine idling, check the vacuum of the vacuum pump assembly.

Standard Pressure:

More than 86.7 kPa (650 mmHg, 25.6 in.Hg)

If the pressure is less than the standard, disassemble and inspect the vacuum pump. If necessary, replace the vacuum pump assembly.

Click here .gif)

HINT:

Always perform this operation check procedure after replacing or servicing the vacuum pump assembly.

(e) Remove the vacuum gauge from the vacuum pump assembly.

(f) Connect the union to check valve hose to the vacuum pump assembly, and slide the clip to secure it.

READ NEXT:

REMOVAL CAUTION / NOTICE / HINT

NOTICE: This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here

DISASSEMBLY PROCEDURE 1. REMOVE END COVER

(a) To prevent the coupling of the vacuum pump assembly from contacting the workbench, support the vacuum pump assembly with wooden blocks or an equival

REASSEMBLY PROCEDURE 1. CLEAN VACUUM PUMP HOUSING

(a) Clean the inside surface of the vacuum pump housing. 2. INSTALL VACUUM PUMP ROTOR

(a) Clean the vacuum pump rotor. (b) Apply engine oil to the

SEE MORE:

COMPONENTS ILLUSTRATION

*1 FRONT WHEEL OPENING EXTENSION PAD LH

*2 FRONT WHEEL OPENING EXTENSION PAD RH

*3 NO. 1 ENGINE UNDER COVER

- -

N*m (kgf*cm, ft.*lbf): Specified torque

- - ILLUSTRATION

*1 REAR ENGINE UNDER COVER LH

DESCRIPTION The airbag sensor assembly has a built-in yaw rate and acceleration sensor and detects the vehicle condition.

The skid control ECU (brake actuator assembly) calibrates the sensitivity of the yaw rate sensor (airbag sensor assembly) based on signals from the steering angle sensor and sp

.gif)