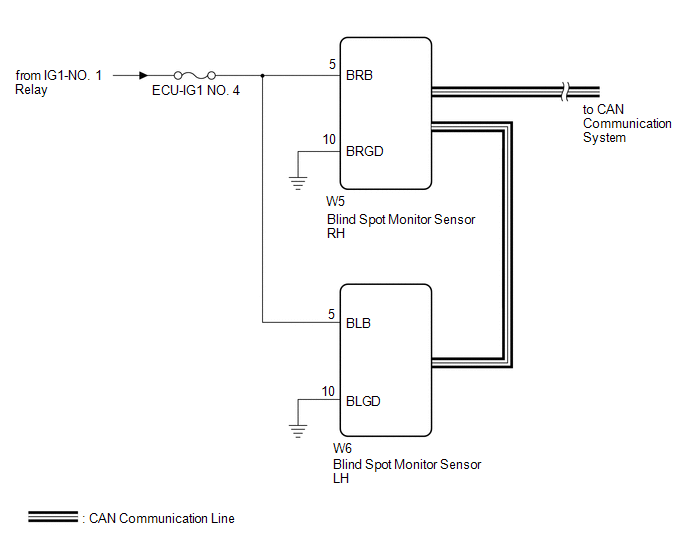

Toyota Camry (XV70): Power Source Circuit

DESCRIPTION

This circuit provides power to operate the blind spot monitor sensor.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

| 1. |

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR RH POWER SOURCE) |

(a) Disconnect the W5 blind spot monitor sensor RH connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

W5-5 (BRB) - Body ground |

Engine switch on (IG) |

11 to 14 V |

|

W5-5 (BRB) - Body ground |

Engine switch off | Below 1 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 2. |

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR RH - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

W5-10 (BRGD) - Body ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. |

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR LH POWER SOURCE) |

(a) Disconnect the W6 blind spot monitor sensor LH connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

W6-5 (BLB) - Body ground |

Engine switch on (IG) |

11 to 14 V |

|

W6-5 (BLB) - Body ground |

Engine switch off | Below 1 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. |

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR LH - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

W6-10 (BLGD) - Body ground |

Always | Below 1 Ω |

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE

|

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)

.gif)