Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during knock control sensor removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

.gif) |

|

Pre-collision System |

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

.gif) |

|

Panoramic View Monitor System |

.gif) |

- Replacement of fuel injector assembly (for Port Injection)

- Replacement of fuel injector assembly (for Direct Injection)

- Replacement of throttle body with motor assembly

- Cleaning the deposits from the throttle body with motor assembly

- Replacement of knock control sensor

| Inspection after repair |

- Poor idle, etc.

- Engine start function, etc.

|

.gif) |

PROCEDURE

1. REMOVE FUEL DELIVERY PIPE

Click here

.gif)

2. REMOVE KNOCK CONTROL SENSOR

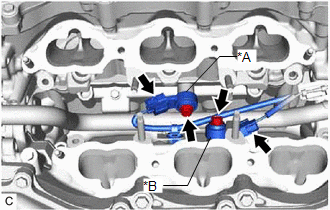

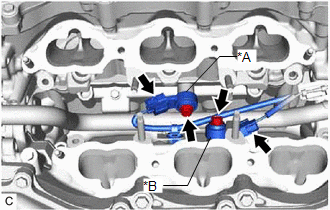

| (a) Disconnect the 2 knock control sensor connectors. |

|

|

*A | for Bank 1 | |

*B | for Bank 2 | | |

(b) Remove the 2 bolts and 2 knock control sensors from the cylinder block sub-assembly.

NOTICE:

If a knock control sensor has been struck or dropped, replace it.

READ NEXT:

INSPECTION PROCEDURE 1. INSPECT KNOCK CONTROL SENSOR

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition

INSTALLATION PROCEDURE 1. INSTALL KNOCK CONTROL SENSOR

HINT: Perform "Inspection After Repair" after replacing a knock control sensor.

Click here

(a) Temporarily install the 2 knock contro

SEE MORE:

REMOVAL CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear axle carrier sub-assembly removal/installation are shown below. Necessary Procedures After Parts

DESCRIPTION When any of the following conditions are met, the skid control ECU (brake actuator assembly) sets the drive output (STPO) ON which operates the stop light control relay (stop light switch assembly) and turns on the stop lights. Illumination Conditions:

Pre-collision brake is operati

.gif)