Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear suspension member sub-assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Rear wheel alignment adjustment |

|

|

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

| Panoramic view monitor system |

| |

| Inspection After Repair |

|

|

CAUTION:

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

.png)

PROCEDURE

1. REMOVE REAR WHEEL

Click here .gif)

2. REMOVE CENTER EXHAUST PIPE ASSEMBLY

for A25A-FKS: Click here

.gif)

for 2GR-FKS: Click here

.gif)

3. REMOVE NO. 2 FLOOR UNDER COVER

Click here .gif)

4. REMOVE NO. 1 FLOOR UNDER COVER

Click here .gif)

5. SEPARATE REAR FLEXIBLE HOSE LH

(a) Remove the bolt and separate the rear flexible hose LH from the rear flexible hose bracket.

6. SEPARATE REAR FLEXIBLE HOSE RH

HINT:

Perform the same procedure as for the LH side.

7. REMOVE REAR STABILIZER LINK ASSEMBLY LH

Click here

.gif)

8. REMOVE REAR STABILIZER LINK ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

9. REMOVE REAR STABILIZER BAR

Click here .gif)

10. REMOVE REAR COIL SPRING LH

Click here .gif)

11. REMOVE REAR COIL SPRING RH

HINT:

Perform the same procedure as for the LH side.

12. REMOVE REAR LOWER COIL SPRING INSULATOR LH

Click here .gif)

13. REMOVE REAR LOWER COIL SPRING INSULATOR RH

HINT:

Perform the same procedure as for the LH side.

14. REMOVE REAR NO. 2 SUSPENSION ARM ASSEMBLY LH

Click here .gif)

15. REMOVE REAR NO. 2 SUSPENSION ARM ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

16. REMOVE REAR NO. 1 SUSPENSION ARM ASSEMBLY LH

Click here .gif)

17. REMOVE REAR NO. 1 SUSPENSION ARM ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

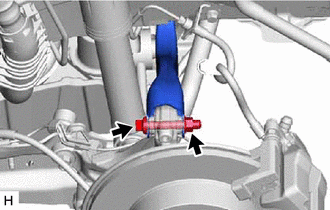

18. SEPARATE REAR UPPER CONTROL ARM ASSEMBLY LH

| (a) Remove the bolt and nut and separate the rear upper control arm assembly LH from the rear axle carrier sub-assembly LH. NOTICE: Because the nut has its own stopper, do not turn the nut. Loosen the bolt with the nut secured. |

|

19. SEPARATE REAR UPPER CONTROL ARM ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

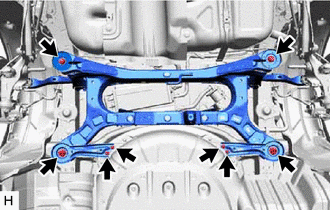

20. REMOVE REAR SUSPENSION MEMBER SUB-ASSEMBLY

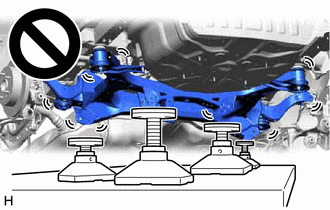

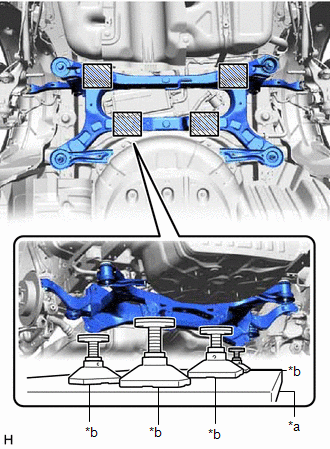

(a) Using an engine lifter and 4 attachments or equivalent tools, support the rear suspension member sub-assembly as shown in the illustration.

- The rear suspension member sub-assembly is a very heavy component. Make sure that it is supported securely.

- If the rear suspension member sub-assembly is not securely supported, it may drop, resulting in serious injury.

NOTICE:

Use attachments or equivalent tools to keep the rear suspension member sub-assembly level.

|

*a | Engine Lifter |

|

*b | Attachment |

.png) |

Attachment Placement Location |

| (b) Remove the 2 bolts, 6 nuts, 2 rear suspension member lower stoppers, rear suspension member lower brace LH and rear suspension member lower brace RH. |

|

(c) Slowly lower the rear suspension member sub-assembly.

NOTICE:

When lowering the rear suspension member sub-assembly, be careful not to damage the vehicle body or other components installed to the vehicle.

(d) Remove the 4 rear suspension member cushions from the rear suspension member sub-assembly.

HINT:

Make sure to place an identification mark on the rear suspension member cushion so that they can be reinstalled to their original positions.

21. REMOVE REAR UPPER CONTROL ARM ASSEMBLY LH

Click here

.gif)

22. REMOVE REAR UPPER CONTROL ARM ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

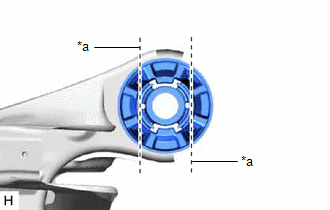

23. REMOVE REAR SUSPENSION MEMBER FRONT BODY MOUNTING CUSHION (for LH Side)

| (a) Using a chisel and hammer, bend the 2 portions of the rear suspension member front body mounting cushion rib. NOTICE: Make sure to bend the 2 portions of the cushion rib until the claws of SST can fit securely. |

|

(b) Apply lubricant to the contact surfaces of the rear suspension member front body mounting cushion.

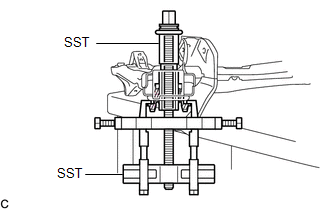

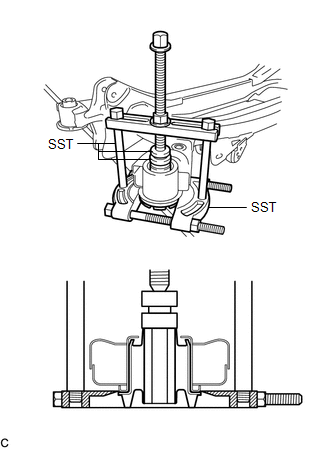

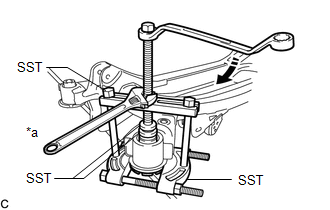

| (c) Install SST as shown in the illustration. SST: 09830-10010 09830-01010 09830-01040 09830-01050 SST: 09950-40011 09951-04010 09952-04010 09954-04010 09955-04061 09958-04011 NOTICE: Apply molybdenum grease to the threads and tip of the SST center bolt before use. |

|

(d) Using SST, remove the rear suspension member front body mounting cushion while applying lubricant into the clearance between the rear suspension member front body mounting cushion and the rear suspension member sub-assembly.

SST: 09830-10010

09830-01010

09830-01040

09830-01050

SST: 09950-40011

09951-04010

09952-04010

09954-04010

09955-04061

09958-04011

NOTICE:

- Set the claws of SST into the rear suspension member sub-assembly securely as shown in the illustration.

- Tighten SST slowly and evenly.

- Be careful as the rear suspension member front body mounting cushion may fly out.

- The rear suspension member front body mounting cushion cannot be reused.

|

*a | Hold |

.png) |

Turn |

(e) Remove SST and the rear suspension member front body mounting cushion from the rear suspension member sub-assembly.

24. REMOVE REAR SUSPENSION MEMBER FRONT BODY MOUNTING CUSHION (for RH Side)

HINT:

Perform the same procedure as for the LH side.

25. REMOVE REAR SUSPENSION MEMBER REAR BODY MOUNT CUSHION LH

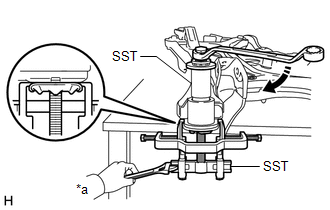

| (a) Install SST as shown in the illustration. SST: 09950-00020 SST: 09950-00030 SST: 09950-60011 09951-00330 NOTICE: Apply molybdenum grease to the threads and tip of the SST center bolt before use. |

|

(b) Using SST, remove the rear suspension member rear body mount cushion LH while applying lubricant into the clearance between the rear suspension member rear body mount cushion LH and the rear suspension member sub-assembly.

SST: 09950-00020

SST: 09950-00030

SST: 09950-60011

09951-00330

NOTICE:

- Tighten SST slowly and evenly.

- Be careful as the rear suspension member rear body mount cushion LH may fly out.

- The rear suspension member rear body mount cushion LH cannot be reused.

|

*a | Hold |

.png) |

Turn |

(c) Remove SST and the rear suspension member rear body mount cushion LH from the rear suspension member sub-assembly.

26. REMOVE REAR SUSPENSION MEMBER REAR BODY MOUNT CUSHION RH

HINT:

Perform the same procedure as for the LH side.