Toyota Camry (XV70): Components

COMPONENTS

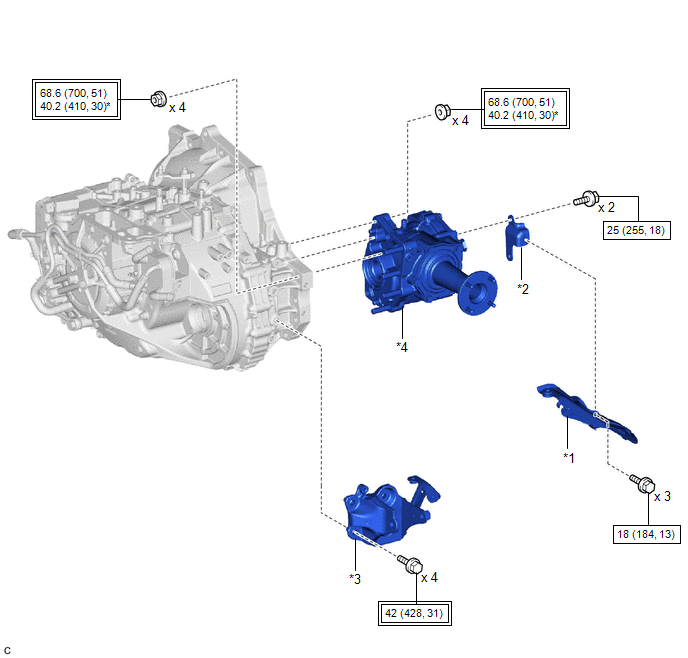

ILLUSTRATION

|

*1 | PROPELLER SHAFT HEAT INSULATOR |

*2 | NO. 1 PROPELLER SHAFT HEAT INSULATOR BRACKET SUB-ASSEMBLY |

|

*3 | REAR ENGINE MOUNTING BRACKET SUB-ASSEMBLY |

*4 | TRANSFER ASSEMBLY |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

* | For use with SST and a union nut wrench |

- | - |

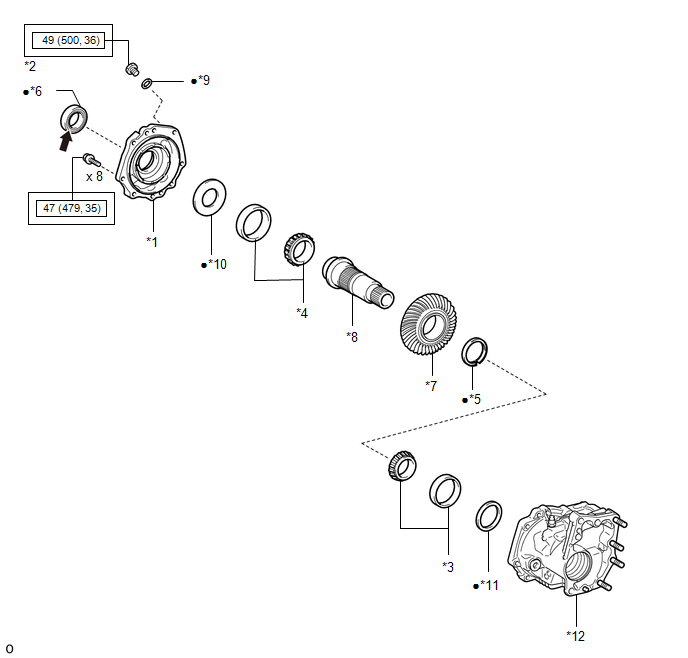

ILLUSTRATION

|

*1 | NO. 1 TRANSFER CASE COVER |

*2 | NO. 1 TRANSFER CASE PLUG |

|

*3 | RING GEAR MOUNTING CASE BEARING LH |

*4 | RING GEAR MOUNTING CASE BEARING RH |

|

*5 | SHAFT SNAP RING |

*6 | TRANSFER CASE OIL SEAL RH |

|

*7 | TRANSFER RING GEAR |

*8 | TRANSFER RING GEAR MOUNTING CASE |

|

*9 | GASKET |

*10 | NO. 2 TRANSFER RING GEAR MOUNTING CASE WASHER |

|

*11 | NO. 1 RING GEAR MOUNTING CASE WASHER |

*12 | TRANSFER CASE |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

● | Non-reusable part |

.png) |

MP grease | - |

- |

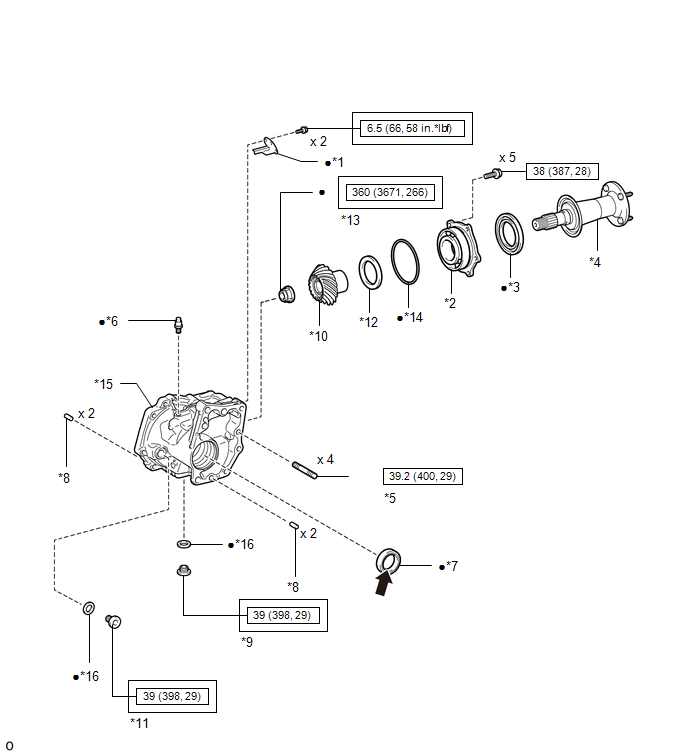

ILLUSTRATION

|

*1 | BREATHER OIL DEFLECTOR |

*2 | FRONT TRANSFER DRIVEN PINION BEARING |

|

*3 | REAR TRANSFER OUTPUT SHAFT DUST DEFLECTOR |

*4 | REAR TRANSFER OUTPUT SHAFT SUB-ASSEMBLY |

|

*5 | TRANSFER AND TRANSAXLE SETTING STUD BOLT |

*6 | TRANSFER CASE BREATHER PLUG |

|

*7 | TRANSFER CASE OIL SEAL |

*8 | TRANSFER CASE STRAIGHT PIN |

|

*9 | TRANSFER DRAIN PLUG |

*10 | TRANSFER DRIVEN PINION |

|

*11 | TRANSFER FILLER PLUG |

*12 | TRANSFER OUTPUT SHAFT WASHER |

|

*13 | TRANSFER GEAR NUT |

*14 | O-RING |

|

*15 | TRANSFER CASE |

*16 | GASKET |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

.png) |

MP grease |

|

★ | Precoated part |

- | - |