Toyota Camry (XV70): Components

COMPONENTS

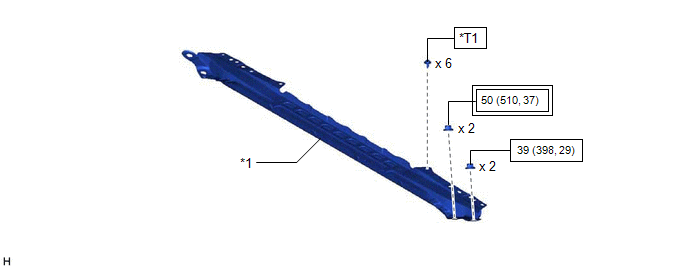

ILLUSTRATION

|

*1 | FRONT CENTER UPPER SUSPENSION BRACE SUB-ASSEMBLY |

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

*T1 | Bolt color black: 8.0 N*m (82 kgf*cm, 71 in.*lbf) Bolt color silver: 8.9 N*m (91 kgf*cm, 79 in.*lbf) |

- | - |

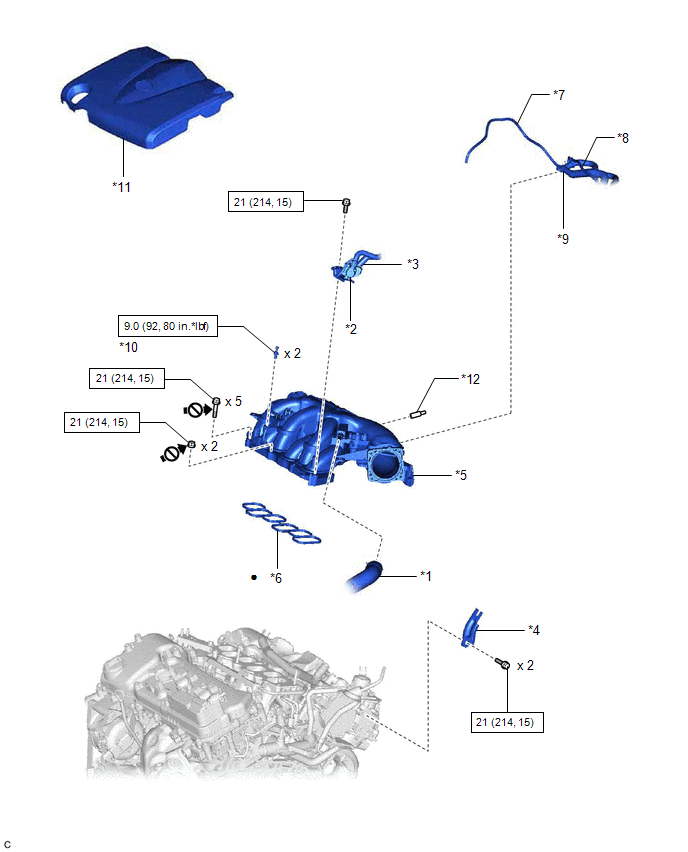

ILLUSTRATION

|

*1 | VENTILATION HOSE |

*2 | PURGE VALVE (PURGE VSV) |

|

*3 | NO. 1 FUEL VAPOR FEED HOSE |

*4 | NO. 2 SURGE TANK STAY |

|

*5 | INTAKE AIR SURGE TANK ASSEMBLY |

*6 | AIR SURGE TANK TO INTAKE MANIFOLD GASKET |

|

*7 | VACUUM HOSE SUB-ASSEMBLY |

*8 | VACUUM HOSE |

|

*9 | NO. 2 AIR TUBE |

*10 | NO. 1 V-BANK COVER BRACKET |

|

*11 | V-BANK COVER SUB-ASSEMBLY |

*12 | PLUG |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

.png) |

Do not apply lubricants (to the threaded parts) |

- | - |

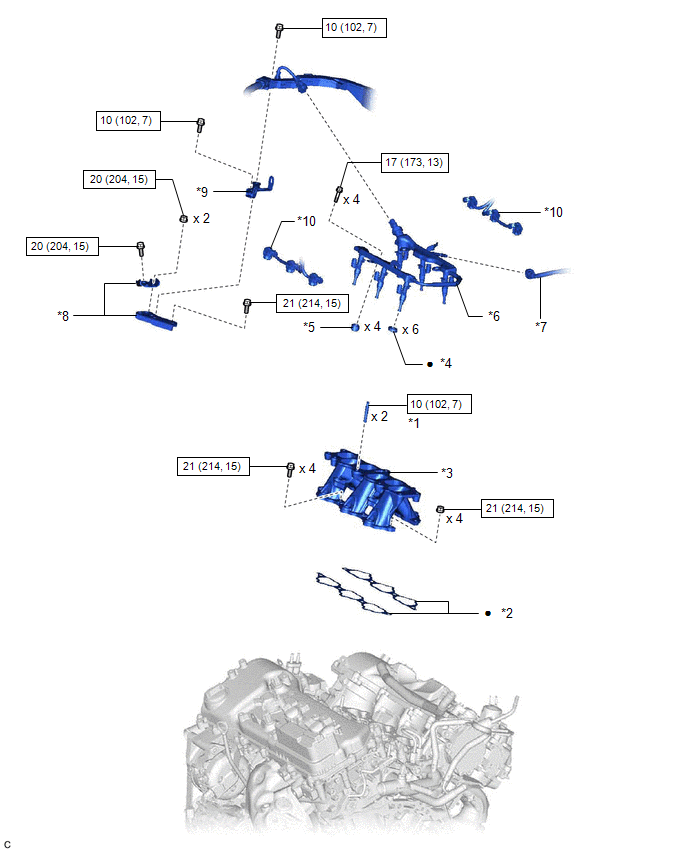

ILLUSTRATION

|

*1 | STUD BOLT |

*2 | NO. 1 INTAKE MANIFOLD TO HEAD GASKET |

|

*3 | INTAKE MANIFOLD |

*4 | INJECTOR VIBRATION INSULATOR |

|

*5 | NO. 1 DELIVERY PIPE SPACER |

*6 | FUEL DELIVERY PIPE WITH SENSOR ASSEMBLY |

|

*7 | FUEL TUBE SUB-ASSEMBLY |

*8 | NO. 2 ENGINE MOUNTING STAY RH |

|

*9 | WIRE HARNESS CLAMP BRACKET |

*10 | NO. 5 ENGINE WIRE |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |