Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

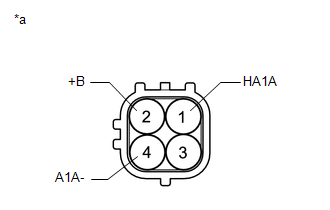

1. INSPECT AIR FUEL RATIO SENSOR (for Bank 1)

| (a) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

1 (HA1A) - 2 (+B) |

20°C (68°F) | 1.6 to 3.2 Ω | |

1 (HA1A) - 4 (A1A-) |

Always | 10 kΩ or higher |

If the result is not as specified, replace the air fuel ratio sensor. |

|

|

*a | Component without harness connected

(Air Fuel Ratio Sensor) | | |

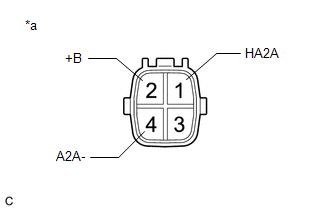

2. INSPECT AIR FUEL RATIO SENSOR (for Bank 2)

| (a) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

1 (HA2A) - 2 (+B) |

20°C (68°F) | 1.6 to 3.2 Ω | |

1 (HA2A) - 4 (A2A-) |

Always | 10 kΩ or higher |

If the result is not as specified, replace the air fuel ratio sensor. |

|

|

*a | Component without harness connected

(Air Fuel Ratio Sensor) | | |

READ NEXT:

INSTALLATION PROCEDURE 1. INSTALL AIR FUEL RATIO SENSOR (for Bank 1)

HINT: Perform "Inspection After Repair" after replacing the air fuel ratio sensor.

Click here

(a) Using SST, instal

COMPONENTS ILLUSTRATION

*1 FRONT FENDER APRON SEAL RH

*2 V-BANK COVER SUB-ASSEMBLY

N*m (kgf*cm, ft.*lbf): Specified torque

- - ILLUSTRATION

*1

SEE MORE:

COMPONENTS ILLUSTRATION

*1 NO. 2 PARKING BRAKE WIRE ASSEMBLY

*2 REAR AXLE HUB AND BEARING ASSEMBLY

*3 REAR AXLE SHAFT NUT

*4 REAR DISC

*5 REAR DISC BRAKE CALIPER ASSEMBLY

*6 REAR FLEXIBLE HOSE

*7 REAR SKID CONTROL SENSOR

*8 RE

DESCRIPTION Each speed sensor detects wheel speed and sends signals to the skid control ECU (brake actuator assembly). These signals are used by the ABS control.

The speed sensor detects the magnetic fields of the speed sensor rotor as it rotates and outputs a pulse signal.

The frequency of the