Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

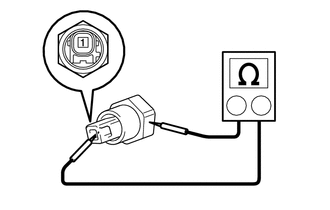

1. INSPECT ENGINE OIL PRESSURE SWITCH ASSEMBLY

| (a) Disengage the clamp to disconnect the wire harness protector. |

|

(b) Disconnect the engine oil pressure switch assembly connector.

(c) Start the engine.

| (d) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the engine oil pressure switch assembly. |

|

(e) Connect the engine oil pressure switch assembly connector.

(f) Connect the wire harness protector.

READ NEXT:

Installation

Installation

INSTALLATION PROCEDURE 1. INSTALL ENGINE OIL PRESSURE SWITCH ASSEMBLY

(a) Apply adhesive to 2 or 3 threads of the engine oil pressure switch assembly.

Adhesive: Toyota Genuine Adhesive 1344,

Components

Components

COMPONENTS ILLUSTRATION

*1 ENGINE OIL PRESSURE SWITCH ASSEMBLY

*2 FRONT FENDER APRON SEAL RH

*3 WIRE HARNESS PROTECTOR

- -

N*m (kgf*cm, ft*lbf): Sp

Removal

Removal

REMOVAL PROCEDURE 1. REMOVE FRONT FENDER APRON SEAL RH

Click here

2. DRAIN ENGINE OIL Click here

3. REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

(a) Disengage the clamp to disco

SEE MORE:

Right Front Wheel ABS Hold Solenoid Control Circuit Short to Battery (C12BB12,...,C12C649)

Right Front Wheel ABS Hold Solenoid Control Circuit Short to Battery (C12BB12,...,C12C649)

DESCRIPTION The ABS solenoid relay and solenoid valves are built into the brake actuator assembly.

The front solenoid valve RH controls the brake fluid pressure of the front wheel cylinder RH of the vehicle.

When this DTC is stored, the fail-safe function operates and the ABS solenoid relay is t

Components

Components

COMPONENTS ILLUSTRATION

*A except Panoramic Moon Roof

- -

*1 TELEPHONE AND GPS ANTENNA ASSEMBLY

*2 TELEPHONE AND GPS ANTENNA ASSEMBLY WITH COVER

*3 COVER

*4 WASHER AND HOLDER

*5 SEAL

*6 TELEPHONE ANTENNA HOUSING

© 2023-2026 Copyright www.tocamry.com

.png)