Toyota Camry (XV70): Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT STABILIZER LINK ASSEMBLY

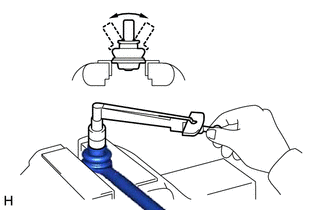

| (a) Inspect the turning torque of the ball joint. (1) Secure the front stabilizer link assembly in a vise using aluminum plates. NOTICE: Do not overtighten the vise. (2) Install the nut to the front stabilizer link assembly stud. (3) Using a torque wrench, turn the stud continuously at a rate of 3 to 5 seconds per turn and take the torque reading on the 5th turn. Turning Torque: 0.05 to 1.96 N*m (0.6 to 19 kgf*cm, 0.5 to 17 in.*lbf) HINT: If the turning torque is not within the specified range, replace the front stabilizer link assembly with a new one. (4) Turn the stud to check that the stud does not catch and there is no play. HINT: If the stud catches or there is play while turning, replace the front stabilizer link assembly with a new one. |

|

(b) Inspect the dust cover.

(1) Check that the dust cover is not cracked and that there is no grease on it.

HINT:

If the dust cover is cracked or there is grease on it, replace the front stabilizer link assembly with a new one.