Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced starter assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision System | |||

|

Memorize steering angle neutral point |

Parking assist monitor system |

| |

|

Panoramic view monitor system |

|

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here .gif)

2. REMOVE BATTERY

Click here .gif)

3. REMOVE COOL AIR INTAKE DUCT SEAL

Click here .gif)

4. REMOVE V-BANK COVER SUB-ASSEMBLY

Click here .gif)

.gif)

.gif)

5. REMOVE INLET AIR CLEANER ASSEMBLY

Click here

.gif)

.gif)

.gif)

6. REMOVE AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE

Click here .gif)

.gif)

.gif)

7. REMOVE ECM

Click here .gif)

.gif)

8. REMOVE BATTERY CLAMP SUB-ASSEMBLY

Click here .gif)

.gif)

.gif)

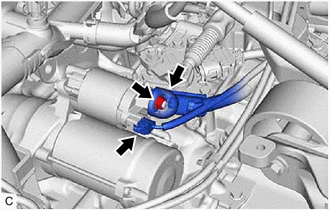

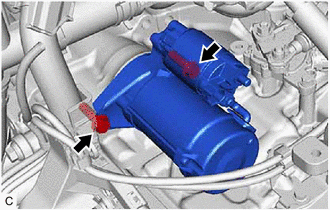

9. REMOVE STARTER ASSEMBLY

| (a) Disconnect the starter assembly connector. |

|

(b) Open the terminal cap.

(c) Remove the nut and disconnect the engine wire from the terminal 30.

| (d) Remove the 2 bolts and starter assembly. |

|