Toyota Camry (XV70): Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during front stabilizer bar removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: w/ Smart Key System

*2: w/o Smart Key System *3: When the ECM is replaced with a new one, reset memory is unnecessary. | |||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision system | |||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

| |

|

Panoramic view monitor system |

| ||

|

Replacement of ECM | Vehicle Identification Number (VIN) registration |

MIL comes on | for A25A-FKS:

for 2GR-FKS:

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

w/ Smart Key System: w/o Smart Key System:

| |

| Inspection After Repair |

| for A25A-FKS:

for 2GR-FKS:

|

|

Replacement of automatic transaxle assembly |

|

| for UB80E Initialization:

for UB80E Registration:

for UA80E Initialization:

for UA80E Registration:

for UB80F Initialization:

for UB80F Registration:

|

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

| ||

| Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

| ||

| Automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

for UB80E: for UA80E:

for UB80F:

|

|

Replacement of ECM*1 | Code registration (Smart key System (for Start Function) |

|

|

|

Replacement of ECM*2 | Code registration (Immobiliser system (w/o Smart Key System)) |

|

|

|

Front wheel alignment adjustment |

|

| w/ Electric Parking Brake System:

w/o Electric Parking Brake System:

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

for Initialization: for Calibration:

|

| Panoramic view monitor system |

for Initialization: for Calibration:

| |

|

Rack and pinion power steering gear assembly |

|

|

|

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

for A25A-FKS: Click here

.gif)

.gif)

for 2GR-FKS: Click here .gif)

.gif)

.gif)

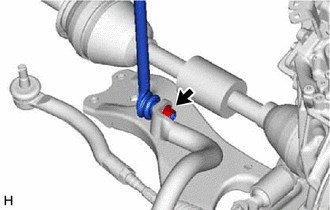

2. REMOVE FRONT STABILIZER LINK ASSEMBLY LH

| (a) Remove the nut and front stabilizer link assembly LH from the front stabilizer bar. NOTICE: Do not damage the boot of the ball joint. HINT: If the ball joint turns together with the nut, use a 6 mm hexagon socket wrench to hold the stud bolt. |

|

3. REMOVE FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

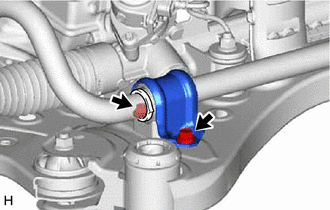

4. REMOVE FRONT NO. 1 STABILIZER BRACKET LH

| (a) Remove the 2 bolts and front No. 1 stabilizer bracket LH from the front frame assembly. |

|

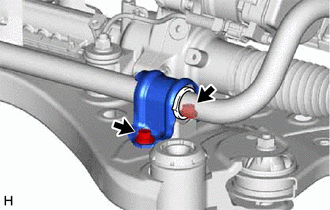

5. REMOVE FRONT NO. 1 STABILIZER BRACKET RH (for A25A-FKS)

| (a) Remove the 2 bolts and front No. 1 stabilizer bracket RH from the front frame assembly. |

|

6. REMOVE FRONT NO. 1 STABILIZER BRACKET RH (for 2GR-FKS)

HINT:

Perform the same procedure as for the LH side.

7. REMOVE FRONT STABILIZER BAR

(a) Remove the front stabilizer bar with 2 front stabilizer bar bushings from the front frame assembly.

8. REMOVE FRONT NO. 1 STABILIZER BAR BUSHING (for LH Side)

(a) Remove the front No. 1 stabilizer bar bushing from the front stabilizer bar.

9. REMOVE FRONT NO. 1 STABILIZER BAR BUSHING (for RH Side)

HINT:

Perform the same procedure as for the LH side.