Toyota Camry (XV70): Components

COMPONENTS

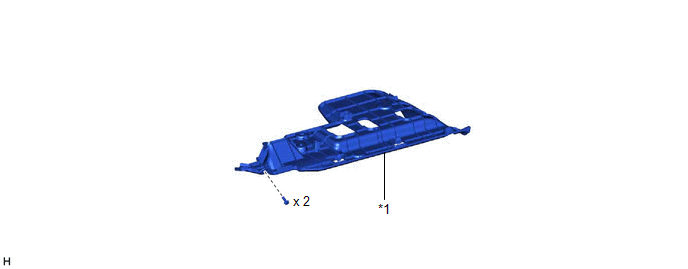

ILLUSTRATION

|

*1 | NO. 1 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY |

- | - |

ILLUSTRATION

.png)

|

*1 | FRONT CENTER UPPER SUSPENSION BRACE SUB-ASSEMBLY |

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

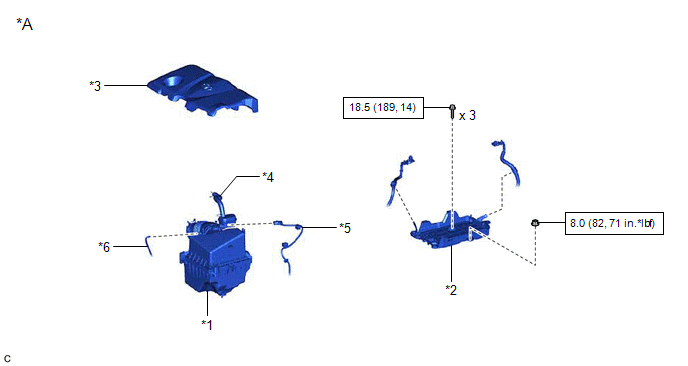

ILLUSTRATION

|

*A | for A25A-FKS |

- | - |

|

*1 | AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE |

*2 | BATTERY CLAMP SUB-ASSEMBLY |

|

*3 | NO. 1 ENGINE COVER SUB-ASSEMBLY |

*4 | NO. 2 VENTILATION HOSE |

|

*5 | MASS AIR FLOW METER SUB-ASSEMBLY CONNECTOR |

*6 | VACUUM HOSE |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

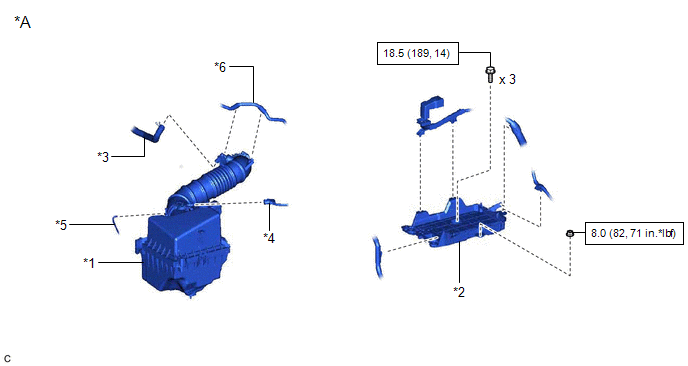

ILLUSTRATION

|

*A | for 2GR-FKS |

- | - |

|

*1 | AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE |

*2 | BATTERY CLAMP SUB-ASSEMBLY |

|

*3 | NO. 2 VENTILATION HOSE |

*4 | MASS AIR FLOW METER SUB-ASSEMBLY CONNECTOR |

|

*5 | VACUUM HOSE |

*6 | NO. 1 FUEL VAPOR FEED HOSE |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

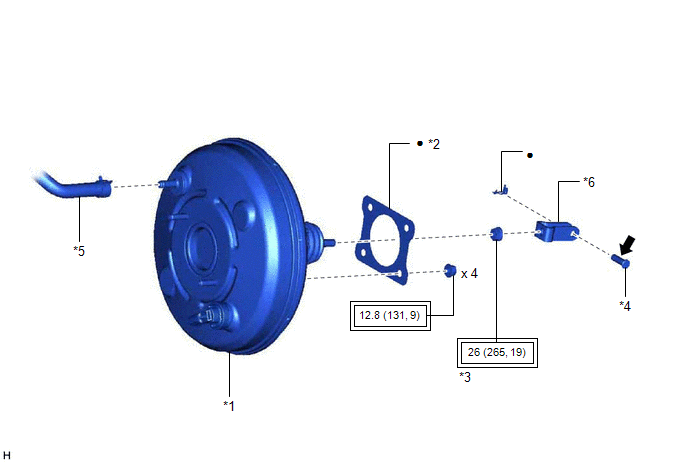

ILLUSTRATION

|

*1 | BRAKE BOOSTER ASSEMBLY |

*2 | BRAKE BOOSTER GASKET |

|

*3 | LOCK NUT |

*4 | PUSH ROD PIN |

|

*5 | UNION TO CHECK VALVE HOSE |

*6 | BRAKE MASTER CYLINDER PUSH ROD CLEVIS |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

● | Non-reusable part |

.png) |

Lithium soap base glycol grease |

- | - |

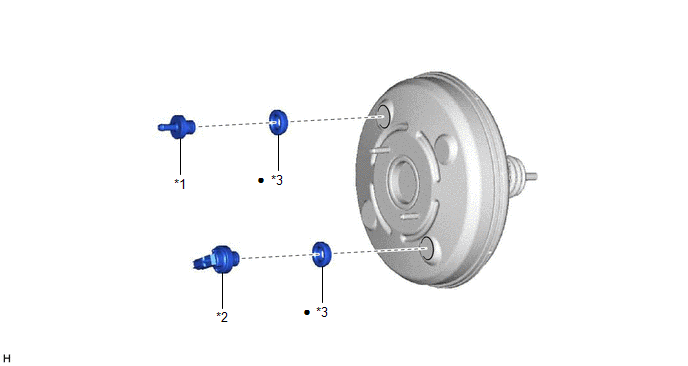

ILLUSTRATION

|

*1 | BRAKE VACUUM CHECK VALVE ASSEMBLY |

*2 | VACUUM WARNING SWITCH ASSEMBLY |

|

*3 | CHECK VALVE GROMMET |

- | - |

|

● | Non-reusable part |

- | - |